Shenandoah FPS Engineering Services

Project overview

- Greenfield offshore FPS

- Production from 5,800-ft-deep subsea wells

- Topside weight control + equipment integration

- 17.5-MW power generation

- BSEE, BOEM, US Coast Guard regulatory compliance

Scope of work

- Detailed topside engineering + design

- Project management + procurement

- Automation + programming

- Process safety analysis

- Construction support

Project summary

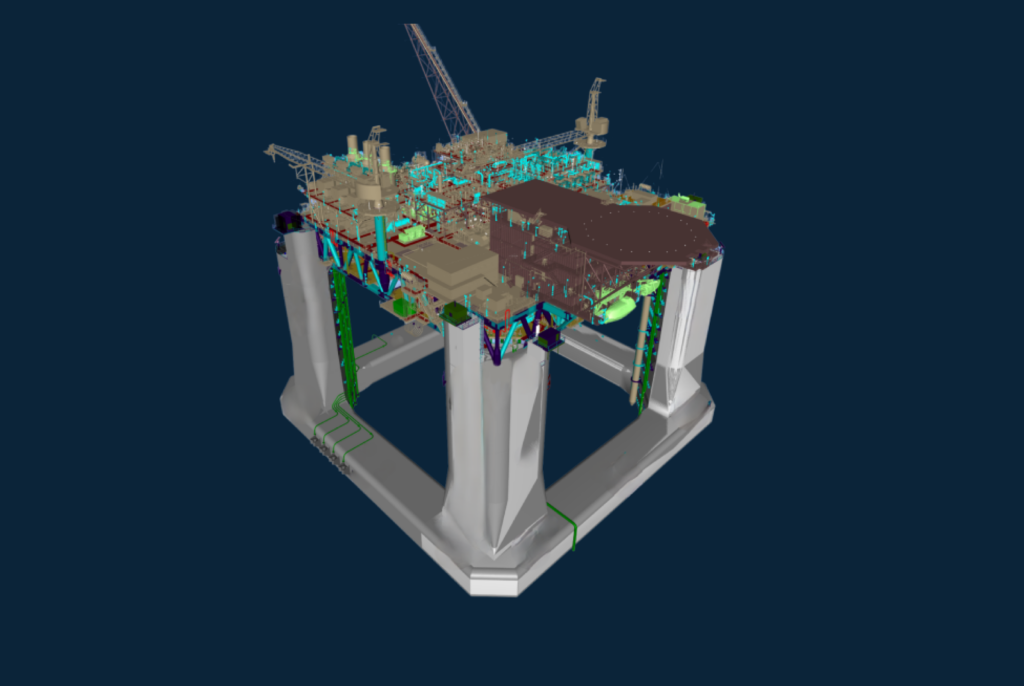

Beacon Offshore Energy enlisted Audubon Companies to supply offshore engineering services, along with procurement and construction support, for the topside of its Shenandoah semisubmersible floating production system (FPS). To streamline cost and schedule, Audubon was contracted by HD Hyundai Heavy Industries, the project’s engineering, procurement, fabrication, and construction (EPFC) team in South Korea. Located in the ultrahigh-pressure Walker Ridge area (Block 52) of the US Gulf, the Shenandoah FPS has a nominal design capacity of 120,000 bbl/d of oil, 140 million standard ft3/d of natural gas, and 40,000 bbl/d of water.

Experienced topside design with repeatable results

Audubon’s knowledgeable, experienced personnel engineered and designed the topside facility and integrated all topside equipment with reliable automation and controls. The Shenandoah topside design also included the interfaces to hull and subsea systems, life-saving equipment, marine and utility systems, power generation, and accommodations. Shenandoah is the third of its kind in best-in-class FPS topside design, refined from Audubon’s designs for Delta House and King’s Quay.