Client

Location

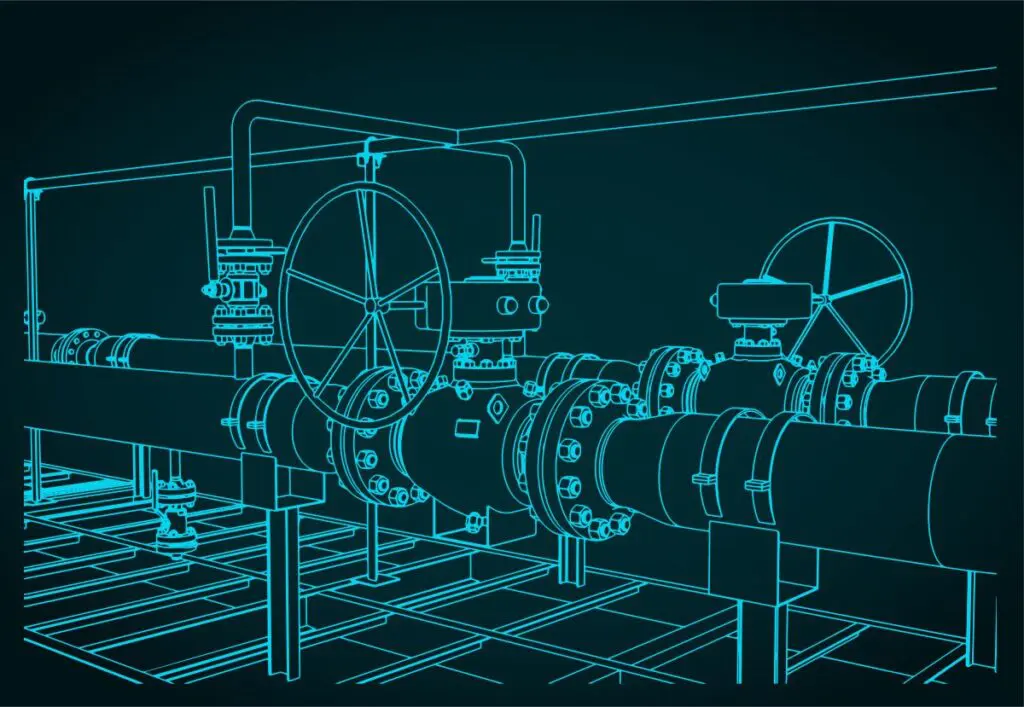

Cypress + Spruce Compressor Stations

Project overview

- Two greenfield compressor stations

- Four 400 GPM amine units and four TEG dehydration units

- Each facility included the installation of ten CAT 3612 engine driven compressors for 75,000 HP of compression

- Cypress and Spruce compressor stations installation included auxiliary balance of plant equipment and E/I infrastructure

Scope of work

- Project management

- Procurement support

- Detail engineering & design

- Process safety analysis

- Construction management & inspection

- Start-up & commissioning

Project summary

The greenfield project was comprised of two compressor stations for a total flow rate of 400 MMSCFD, located near Toyah, TX. The two facilities included a total of four 400 GPM amine units and four TEG dehydration units. Each facility included the installation of 10 CAT 3612 engine driven compressors for 75,000 HP of compression. The facility execution and installation model was based on a modularized approach for standard packages and pipe rack modules. Along with the major equipment, the Cypress and Spruce compressor stations installation included auxiliary balance of plant equipment and E/I infrastructure.

Related Featured work