Client

Location

PLC Upgrade + Online Cutover

Project overview

- PLC upgrade (PLC5 to ControlLogix)

- Project management

- Procurement

- Programming & graphics development

Scope of work

- Functional design specification

- As-built control narratives, cause & effect diagrams, & configuration sheets

- PLC & SIS panel design drawings

- Programming & configuration

- Cutover procedure development

- Factory acceptance testing (FAT)

- Site acceptance testing (SAT) & commissioning

- Operator training & start-up support

Project summary

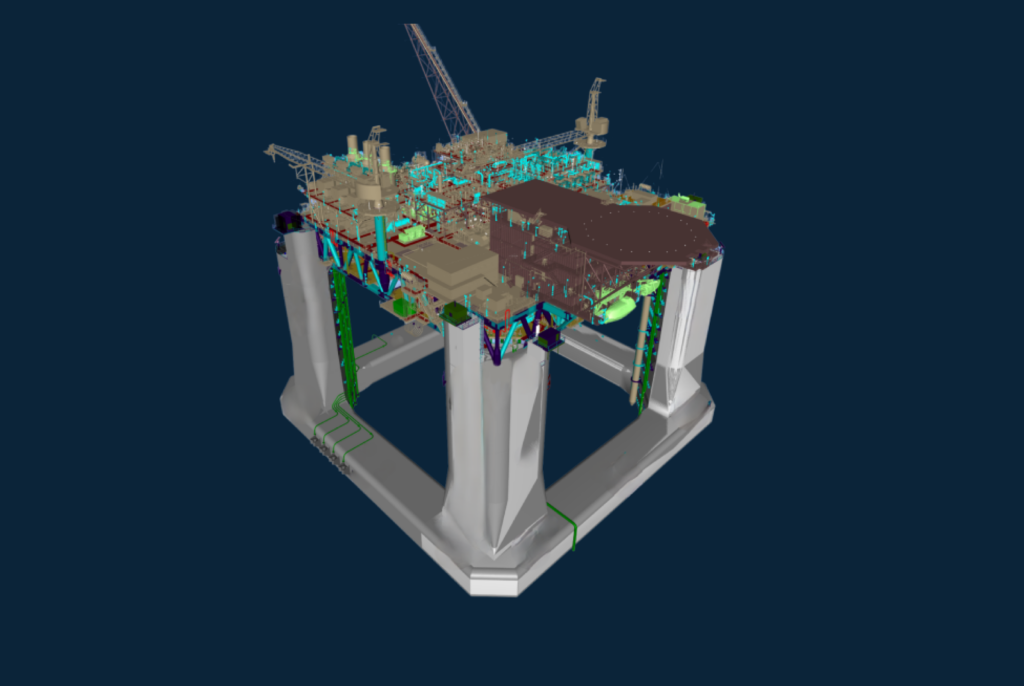

An offshore platform operator in the Gulf of Mexico enlisted Audubon’s automation and control team to upgrade the existing facility’s programmable logic controller (PLC), safety instrumented system (SIS), and human-machine interface (HMI) systems. The scope of work included project management, procurement, programming, graphics development, testing, and onsite deployment. A detailed online SIS and basic process control system (BPCS) cutover procedure was also developed and tested before implementation to eliminate facility downtime.

Related Featured work