Pipeline Integrity Program for Refinery Facility

Project overview

- Regulatory analysis (PHMSA 192 & 195 vs OSHA 1910.119)

- Field data collection (mobile platform)

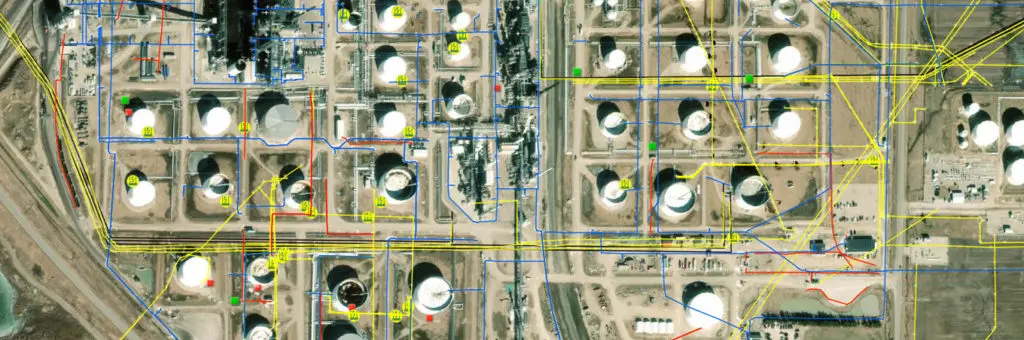

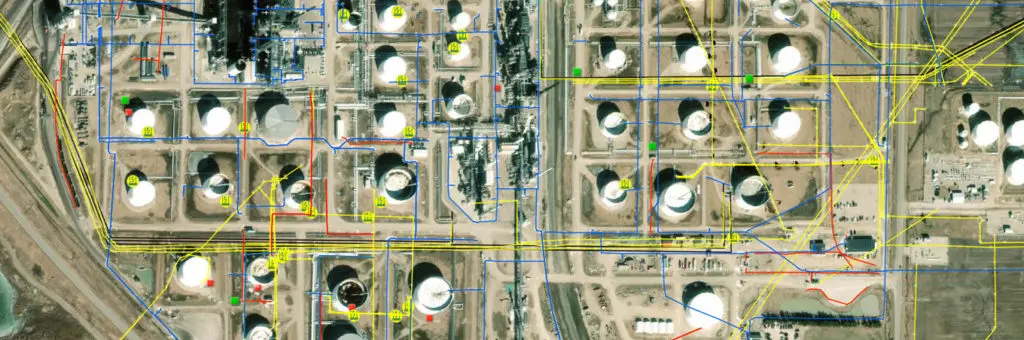

- ESRI survey 123/ArcCollector based

- Computerized maintenance monitoring system integration

- ArcOnline custom maps and dashboards

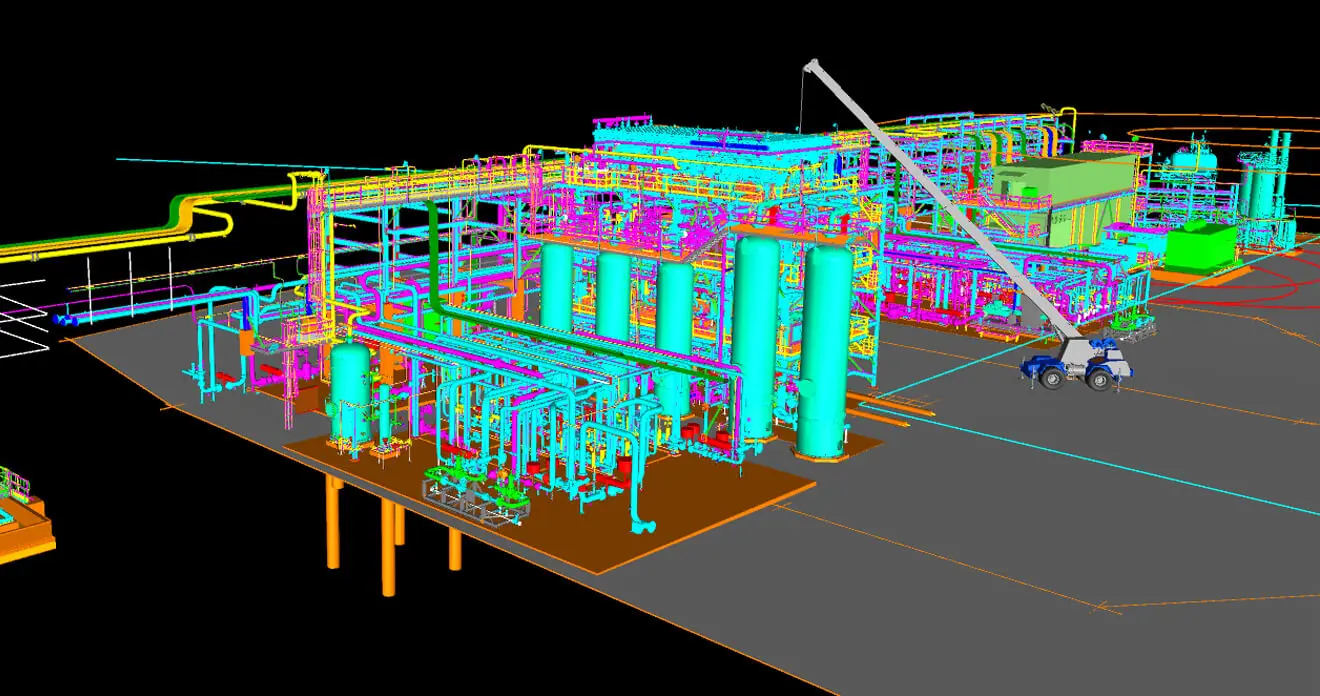

- Locate & identify plant piping

- Develop piping system circuits

- Remote data collection and analyses

- Pipeline centerlines & point feature attributes

- CP system design, installation & commissioning

- Data management & technical support

Scope of work

- O&M data review

- Evaluation of existing CP systems

- Data integration

- Data sets & intersects

- Anomaly spatial development

- Data analysis

- Documented threats

- Risk reduction

- Preventative & mitigative measures

Project summary

An existing cathodic protection (CP) system had exceeded its design life at a major refinery. The system had lost effectiveness and no longer provided adequate external corrosion protection for buried piping and on-grade tank base plates. Audubon was contracted to develop and implement a pipeline integrity management program at the refinery for below-grade facility piping.

The scope of work included field data collection, data integration, analysis, and evaluation of corrosion protection for the existing plant piping. To protect against future corrosion, our NACE-certified team provided design, installation, and commissioning services for the new cathodic protection and monitoring system.

Two years of maintenance and technical support were also included, and data ownership and online systems were maintained by Audubon.