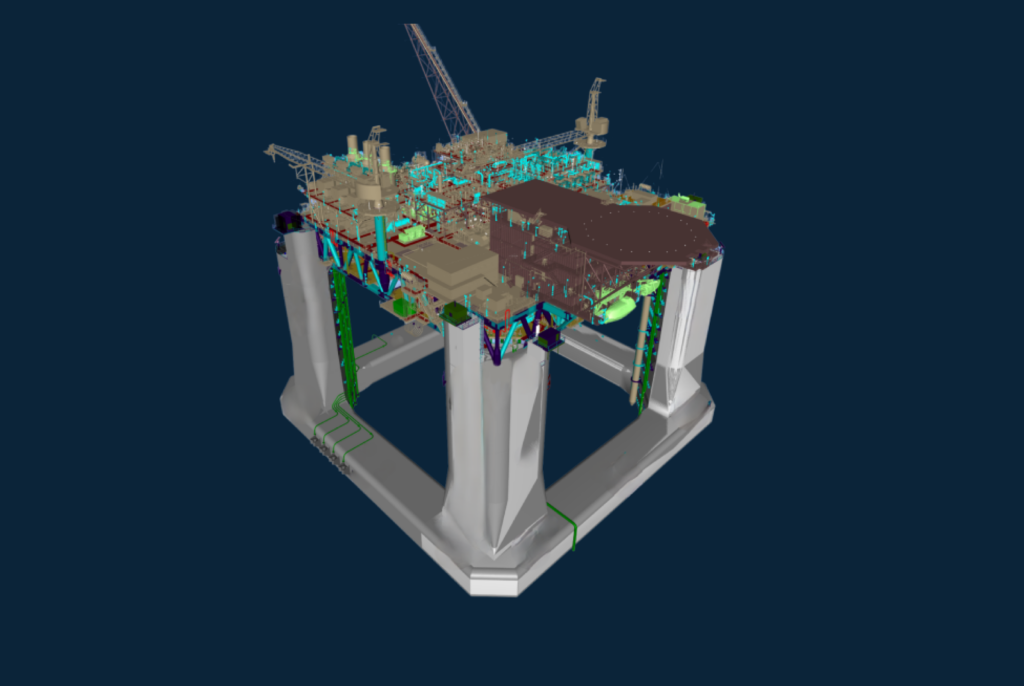

Davy Jones I + II Process + Satellite Facilities

Project overview

- Greenfield

- Production & satellite facility

- Deep drill high pressure, high temperature well

- Gas production with condensate

- Fixed platform designed for 75mcfd

- Shallow water facility: 20-ft. water depth

- Designed to GOM standards

- Production equipment

- Amine plan

- 8-pile & 4-pile production deck

Scope of work

- FEED

- Detail design

- Topside engineering

- Process automation

- Project management

- Start-up & commissioning

- Construction management

- Vendor surveillance

- Paint & I&E inspections

- HSE oversight

- Procurement & expediting

Project summary

Audubon provided FEED, engineering, procurement, EPCM, project management, and commissioning & start-up for the Davy Jones process and satellite facilities.

The project included process modeling, equipment sizing and design, electrical engineering, instrument design, high CO2 and H2S concentrations, and amine treating. We designed jackets, decks, flare booms, and heliport—and collaborated with the well design team on process and interface issues.

We provided construction management and vendor surveillance for the fabrication outfitting and offshore installation of the 8-pile and 4-pile platforms, paint inspection, I&E inspection, onsite cost tracking, material tracking, and HSE oversight.

We integrated with the client’s project management team and provided constructability reviews, contractor assessments, and operability input for the two ultra-deep gas production facilities. The construction team coordinated with contractors and vendors and managed logistics throughout South Louisiana and South Texas.