Want to share this article?

Optimizing FPSO Topside Structure Design Not a Simple Task

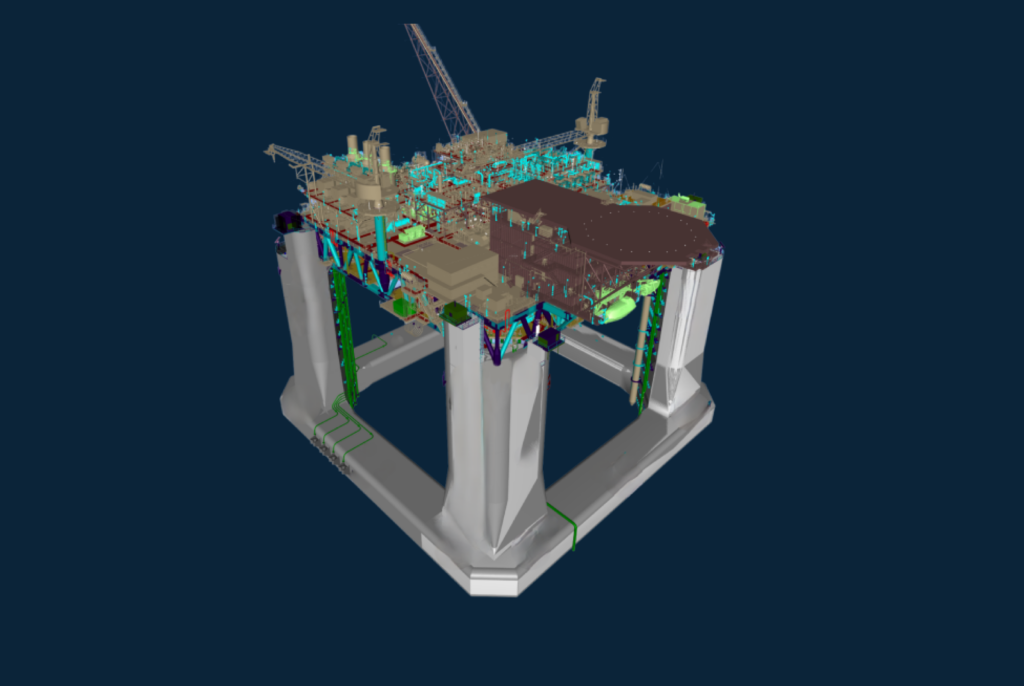

Floating production storage and offloading (FPSO) vessels are playing critical roles in extracting and offloading liquid and gas hydrocarbons from deepwater and ultra-deep subsea wells.

These multipurpose ships effectively extract, store, and offload hydrocarbons in the most remote of locations, while also remaining redeployable to other locations once a well has run dry. However, for FPSOs to be effective at what they do, a considerable amount of design and optimization must go into the topside structures.

Organizing layouts and systems into a standardized modular design based around safety and efficiency regulations and standards provides numerous benefits. First, placing production-intensive units and flares away from living and control centers creates a more effective safety buffer, while integrating pipe structures into the various modules allows for a more efficient quick connect of piping across the ship. Integrating factory-tested plug-and-play I/O systems and electrical connections with pre-fab cord sets into modules encourages rapid installations with fewer termination errors and a shorter pre-commissioning phase. An optimized modular design also allows hydrocarbon-specific processing units to be swapped in and out depending on the type of well the FPSO will be deployed.

Another consideration designers must make is in the weight and alignment of the modular structures being added. If you create too heavy of a module, installation may require more heavy-duty lifting equipment or the separation of the module into two smaller sections. Generators, compressors, and stabilizers should also be aligned in specific places on the ship to maximize their effectiveness and reduce mechanical stresses.

FPSO designers must consider all of these ideas and more while also working within the tight framework of regulatory requirements concerning the vessel’s topside structures as well as the budget of the buyer. However, when done mindfully, a quality FPSO topside design has the opportunity to provide value, flexibility, and efficiency to the deploying entity for many years.