Want to share this article?

Many Benefits of Modular Processing Equipment

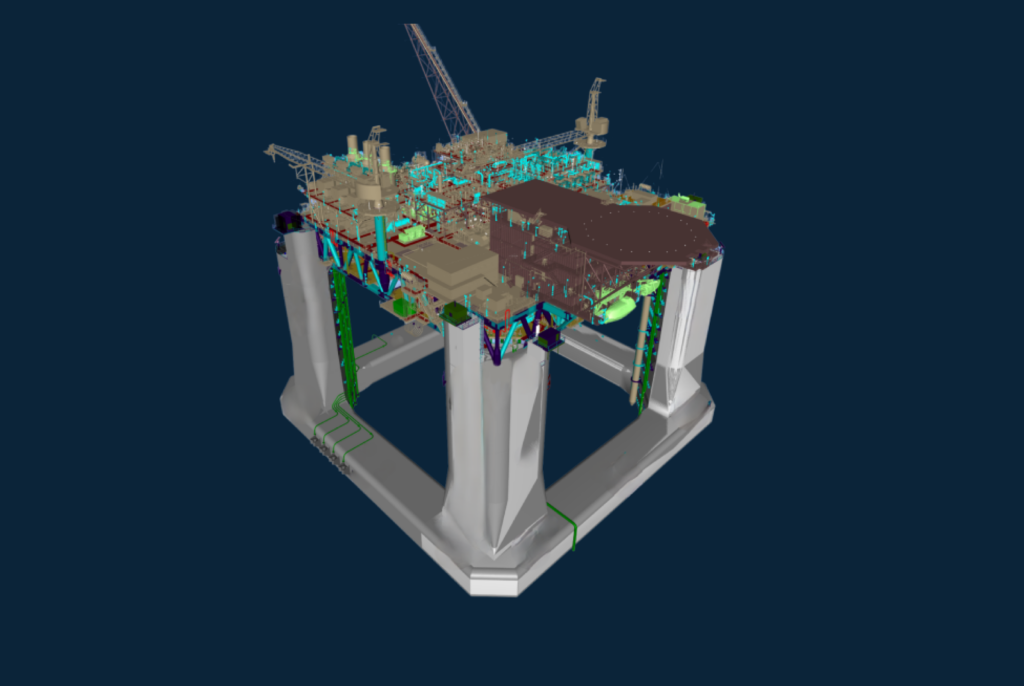

The construction of refineries, distillation plants, and drilling platforms has traditionally involved a systematic, piece-by-piece approach.

Parts are shipped in, and systems are incrementally built with connections scattered throughout the design. This approach has typically required a large construction crew and significant time and effort. However, engineers in both upstream and downstream markets have gradually taken on a new approach to design and construction: modularity.

A modular approach to process design and implementation provides numerous benefits. Each module can be assembled in a controlled environment where they ultimately are factory acceptance tested (FAT) upon completion. The modules — sometimes referred to as “skids” — can also be customized with integrated pipe structures, factory-tested plug-and-play I/O systems, and electrical connections to allow for quicker, more efficient interconnection of subsystems across the entire process chain. Process connections can also be gathered into one location in the module to improve the connection process further.

This level of integration may cost a bit more in up-front design and construction; however, money is saved in the later phases. Smaller crews are required for construction and testing. Connections are more centralized and easier to make. Also, fabrication of modules can be done indoors unlike traditional construction, further speeding up the overall process. This culminates into more rapid installations with fewer termination errors and a shorter pre-commissioning phase.

In some highly optimized modular designs, enough flexibility is inherently built in to allow for even greater enhancement. For example, a well-designed module may allow for the interchange of hydrocarbon-specific processing units based on the type of deployment. This is particularly advantageous on mobile deployments, such as floating production, storage, and offloading (FPSO) vessels, as modules can be pulled off after one contract is complete and updated with components suitable for a different deployment type.