Want to share this article?

Basics of Subsea Pipeline Engineering

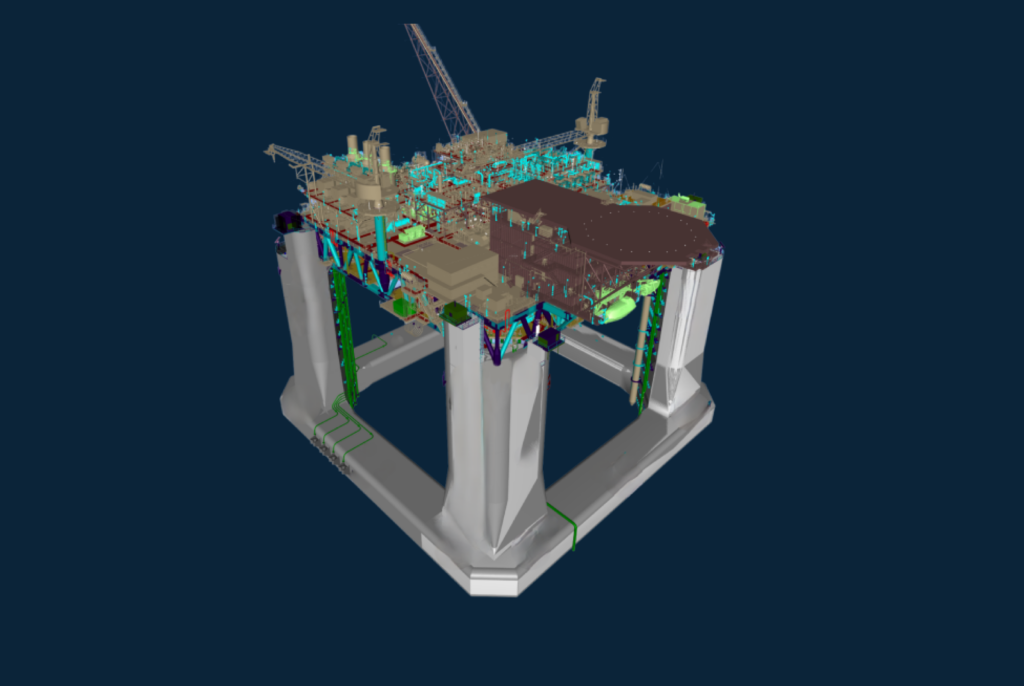

As the search for and extraction of hydrocarbon resources has moved offshore and into deeper waters, new subsea extraction and transportation technologies have been developed, including the subsea pipeline.

To be fair, the use of petroleum-carrying pipeline in bodies of water isn’t entirely a modern phenomenon; the Allied forces of World War II ran secret pipelines across the English Channel from Britain to France to prevent fuel shortages. However, today’s subsea pipelines are cheaper, safer, and more efficient than ever.

Designing a modern subsea pipeline takes more than just knowing basic engineering principles. The creation and implementation of an offshore pipeline design requires a multi-disciplinary approach. Specific knowledge in the fields of thermodynamics, hydrodynamics, chemistry, geological science, and materials science are all necessary to effectively engineer offshore pipeline infrastructure. Designers must use that knowledge to build a subsea structure that can safely and effectively function while also preventing scenarios that can negatively impact it: localized and large-scale buckling, fatigue failure, improper pressurization, on-bottom instability, and even line fracturing. Other considerations such as water temperature and current, internal and external pressure, fluid constituents, soil consolidation, and wellhead or rig status must also be taken into account.

Several processes go into subsea pipeline development including route management, steel and corrosion-resistant alloy selection, stress reduction, and stability management. While a direct straight-line route can work in the simplest of cases, subsea obstacles, protected environments, and even political boundaries can cause a route to be more complex. The choice of quenched and tempered, thermo-mechanical treated, or accelerated cooled steels and a wide variety of thermal and corrosion-resistant coatings must all be considered carefully. Pipe width and thickness must be sufficient to do the job, while pipelay methods must be appropriate to the undersea topography. In cases where the pipeline is not in contact with the seabed for significant spans, strain-based designs are required to prevent vertical and sideways buckling. In the end, a considered subsea pipeline design implemented well will yield several decades or more of dependable service.