Want to share this article?

Gauging Safety in the Oil and Gas Industry

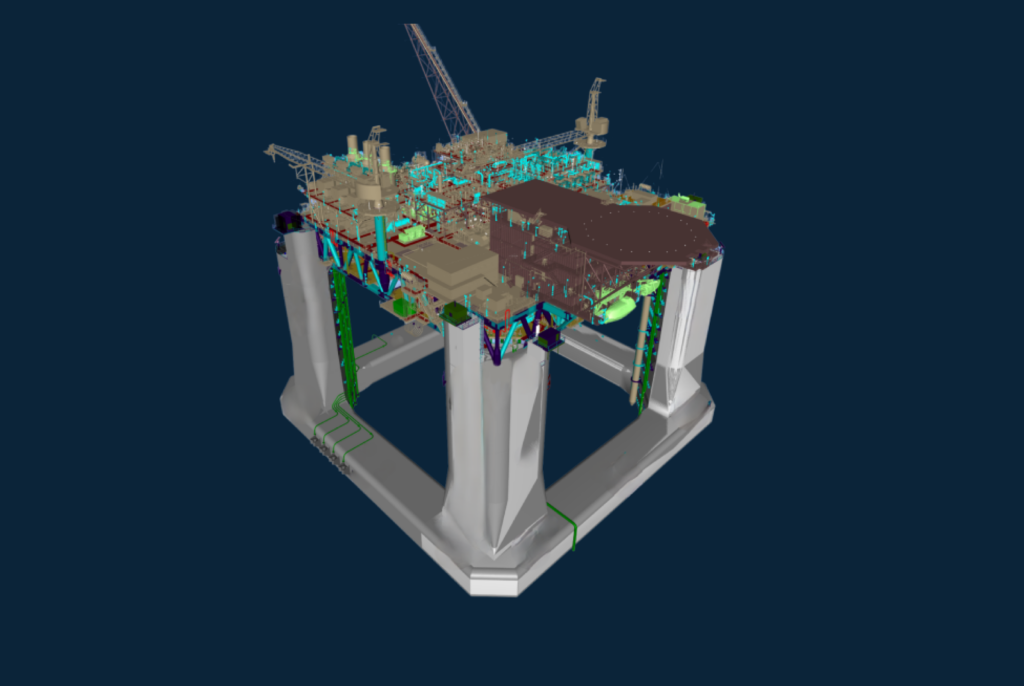

A series of offshore platform accidents in 1969 and 1970 in U.S. waters highlighted the importance of environmental and human safety in the oil and gas industry.

Where the idea of safe processes and designs weren’t a substantial consideration beforehand (PDF), federal oversight and industry watchdogs helped usher in new “recommended practice documents” and regulatory requirements. Since then, worker safety has continued to be a sought-after improvement to oil and gas operations, additionally so in the aftermath of the Deepwater Horizon explosion.

But how is safety commonly gauged today, and how is the industry improving its safety record? Common gauges for measuring safety in the oil and gas industry include the lost-time-incident (LTI) rate and total-recordable-incident (TRI) rate. (The names may vary slightly among organizations, but the idea remains the same.) The LTI rate is a mathematical calculation that considers the number of injuries and illnesses that prevent a worker from completing a full assigned shift as well as the total number of employee work hours in a specific time period. TRI, on the other hand, considers any recordable singular event or exposure at the workplace that resulted in medical treatment or first-aid; this includes job-related fatalities as well as illnesses and injuries.

A 2014 study published in Oil & Gas Journal examined safety statistics from four major sources around the world. Looking at both onshore and offshore data from one of those sources, the International Oil and Gas Producers Association (OGP), the researchers found that drilling safety has consistently improved from 2006 to 2011. However, drilling activities still held a higher TRI rate over petroleum refining, chemical manufacturing, and pipeline transportation, reminding the industry there’s always more safety work to be done. The study also looked at some of the major causes of accidents in onshore and offshore drilling, finding “struck by” incidents to be the most common cause for fatalities in the industry. Onshore “struck by” fatalities were largely attributed to motor vehicles, while offshore fatalities were predominately related to unexpected line slackening and tightening as well as lifting and craning mismanagement.

More recent statistics reported by the International Association of Drilling Contractors (IADC) indicate continuing safety improvement among its global members in 2013, quoting an eight percent reduction in TRI, presumably from the year before. In their report they listed 2,386 recordable incidents, with nearly 800 of them involving fingers. IADC found that most recordable incidents were “caught between” or “struck by” incidents, backing up the findings published in Oil & Gas.