Want to share this article?

The Many Industry Benefits of 3D Laser Scanning

The survey, design, operation, improvement, and asset management of downstream facilities are complicated processes that have evolved with the advent of computing technology.

The development of modeling software, process control software, and other automation tools has benefited the industry greatly. Another such tool that is increasingly used is 3D laser scanning technology. When compared to traditional methods, 3D laser scanning has the potential to reduce follow-up visits and maintenance on site, improve safety, and increase flexibility for future brownfield modifications, but what are the primary ways this technology is being used in the oil and gas industry?

One of the more obvious industry uses involves the development of a 3D terrain survey of a proposed upstream or downstream site. The resulting models can then be used to develop terrestrial and nautical charts and reports. The data associated with the scan can also be used in seismic evaluations, field development, and site construction – from pipelines to storage facilities.

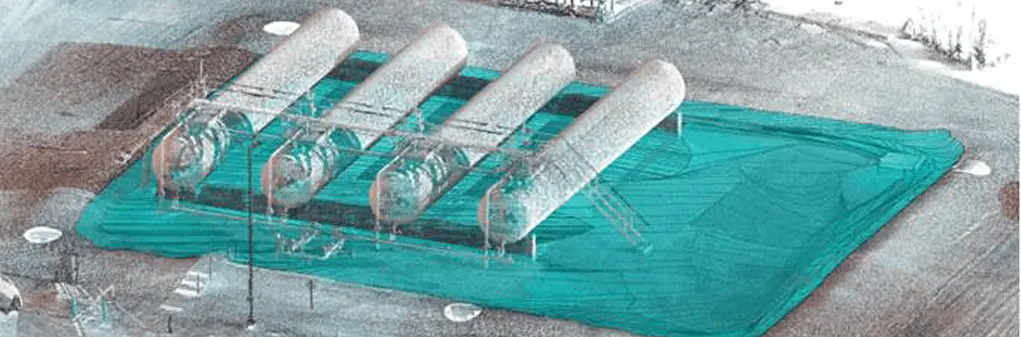

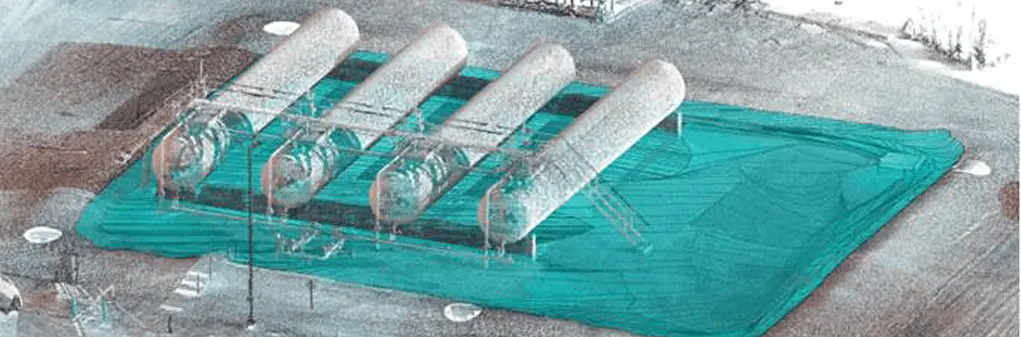

Using a variety of 3D laser scanning tools, the existing, as-built conditions of a facility can also be captured as millions of data points, which can then be imported into 3D modeling software for creating a realistic, to-scale image of the facility. That model can then be tweaked as part of a brownfield design or compared to and contrasted with a new design, utilizing “clash detection” to determine any weaknesses or errors in either of them.

An additional advantage of 3D laser scanning an existing facility is the ability to provide physical data for asset management activities. This may include quantity surveys, asset documentation, condition monitoring, tank calibration, maintenance support, and intelligent plant modeling. For example, stockpiles of coke at a refinery can be scanned to give quicker, more accurate quantity estimates. If a refinery changes hands, 3D documentation of the facility’s components provides a more accurate asset count. Using 3D laser scanning for generating volumetric scans of tanks or maintenance profiles of a facility also prove useful to operators and managers.