Want to share this article?

Recompression Technologies Will Play a Pivotal Role in the Future of Oil and Gas Transportation

Though in recent years rail has become an increasingly popular method of transporting gas from oilfields and processing facilities to the market, pipelines still remain the most commonly used transmission option amongst producers.

On average, over 15,000 miles of natural gas pipeline is installed each year globally and as the demand for gas throughout the world continues to grow, this trend will likely continue.

Compressors (and/or compressor stations) serve as the engines that make oil and gas transmission not only possible, but also economical. As product travels through pipelines, it loses kinetic energy and slows down. Eventually, it reaches a point where it can no longer maintain its forward momentum and it needs to be repressurized.

A number of different factors contribute to how often this repressurization process needs to occur (e.g., pipe diameter, product temperature, gradient) but on average it is required for every 50 – 70 miles of pipe.

With higher volumes of gas being pumped through existing pipelines in an effort to meet rising energy demands, the stress being put on compressors and compressor stations is increasing.

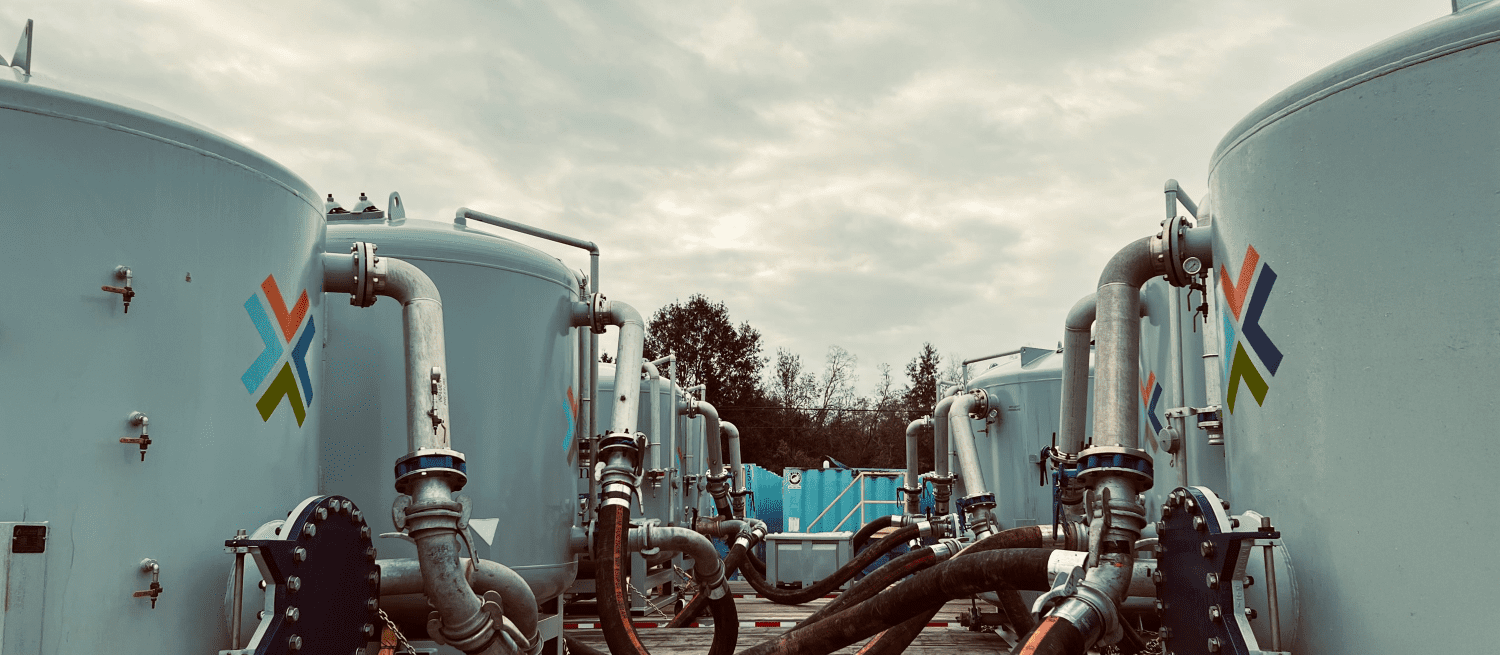

In light of this, many operators and midstream companies are on the lookout for new and advanced recompression technologies that can efficiently and reliably handle higher capacities without resulting in a larger environmental footprint.

Flexibility and modularization are also important characteristics that operators are looking for in their compressors. In general, the cost of actually commissioning a compressor unit greatly outweighs the initial cost of the compressor itself. As a result, options that allow for easy installation and flexible use are becoming more and more popular.

While some of the most advanced technology being used today such as active magnetic bearing applications and supersonic compressors can be seen in North America’s booming shale plays – which are currently the target of a great deal of funding – many other operators around the globe are taking advantage of technologies that fit the unique demands of the market they are in as well.