US Gulf Coast Petrochemical Plant Expansion

Project overview

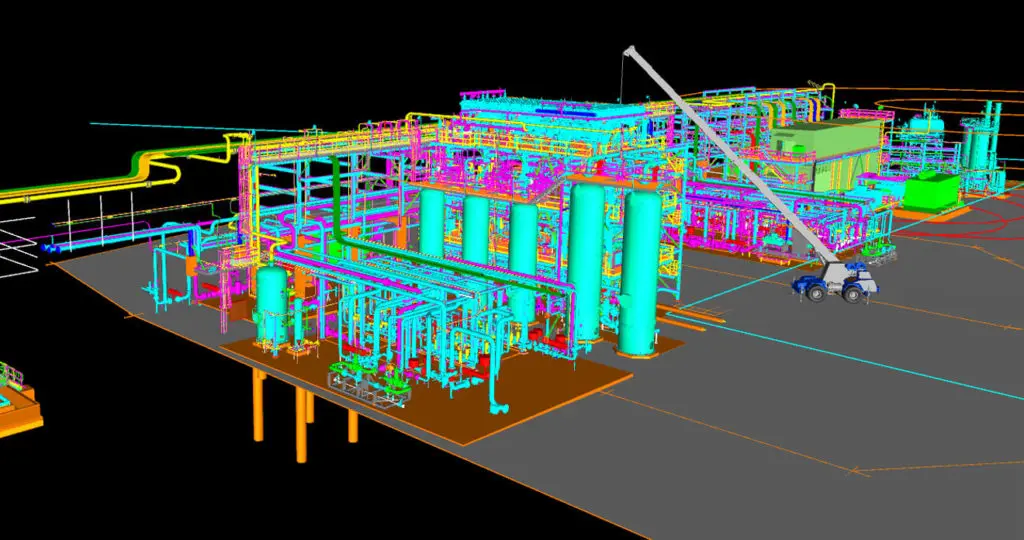

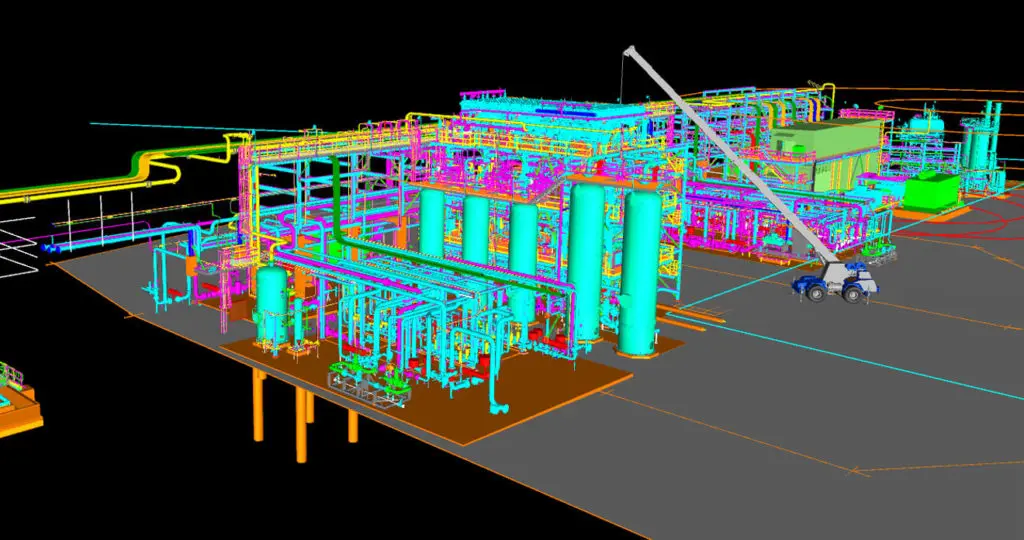

- Brownfield expansion with multiple upgrades

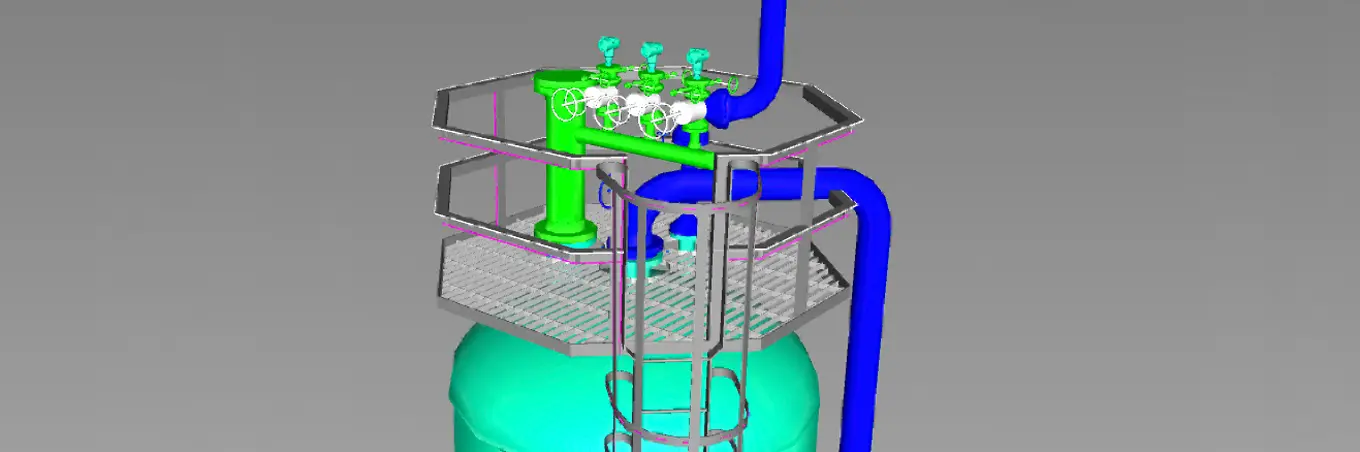

- 400,000-lb/hr ISBL ethylene-treating unit

- Underground well storage

- Extraction & purification

- Pipeline grid distribution

Scope of work

- Conceptual study

- FEED

- Detailed engineering & design

- Project management

- Process safety analysis

- Automation & control

- Procurement

- Construction management

- Inspection

- Operational technical writing

Project summary

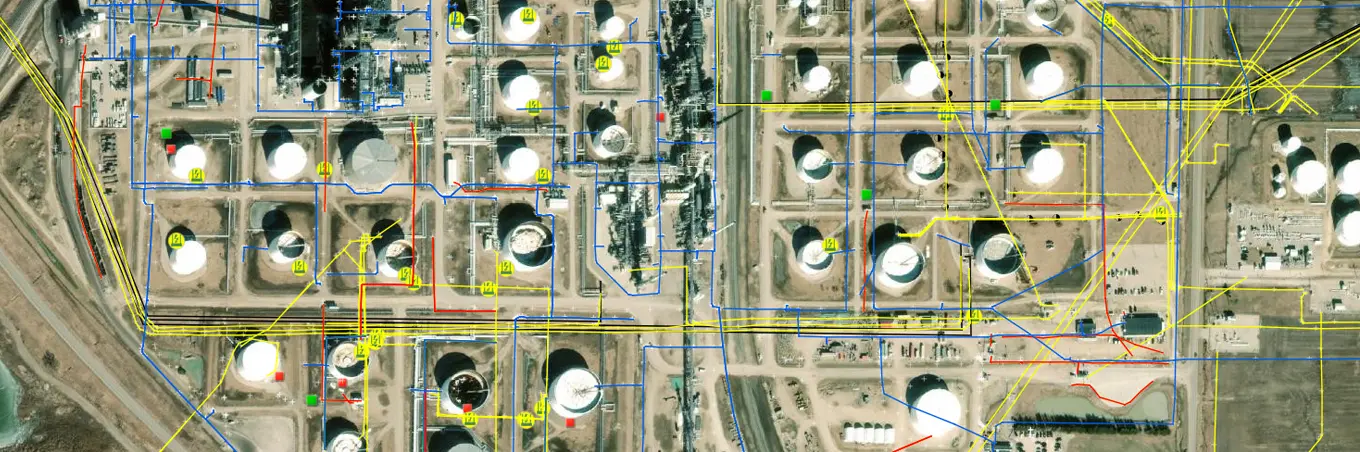

To support petrochemical plant expansion of the Targa terminal in Mont Belvieu, Texas, Audubon provided design services for Chevron Phillips Chemical, including engineering, procurement, and construction management (EPCM). The brownfield expansion comprised a new 400,000-lb/hr inside-battery-limit (ISBL) ethylene-treating unit, underground well storage, extraction and purification processes, and pipeline grid distribution.

Audubon communicated with two outside-battery-limit (OSBL) engineering contractors to accommodate the terminal’s existing systems. Our team also acted as the procurement agent to Chevron Phillips Chemical for all ISBL and OSBL equipment and subvendors.

The successful project involved 105,000 man-hours worked with zero recorded accidents—from front-end engineering and design (FEED) to construction.