Owner’s Engineering for Port Arthur Methanol Plant

Project overview

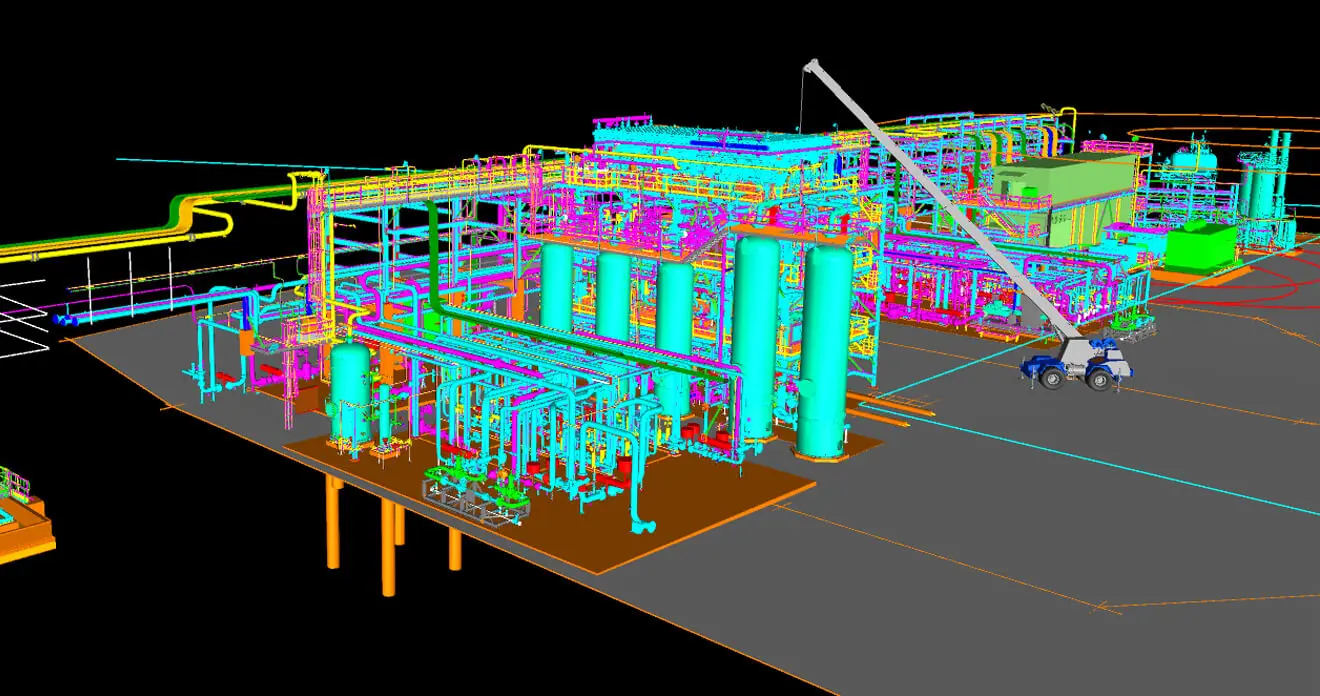

- 1.8-MTPA methanol production plant utilizing MegaMethanol technology

- Inlet gas-treating and conditioning

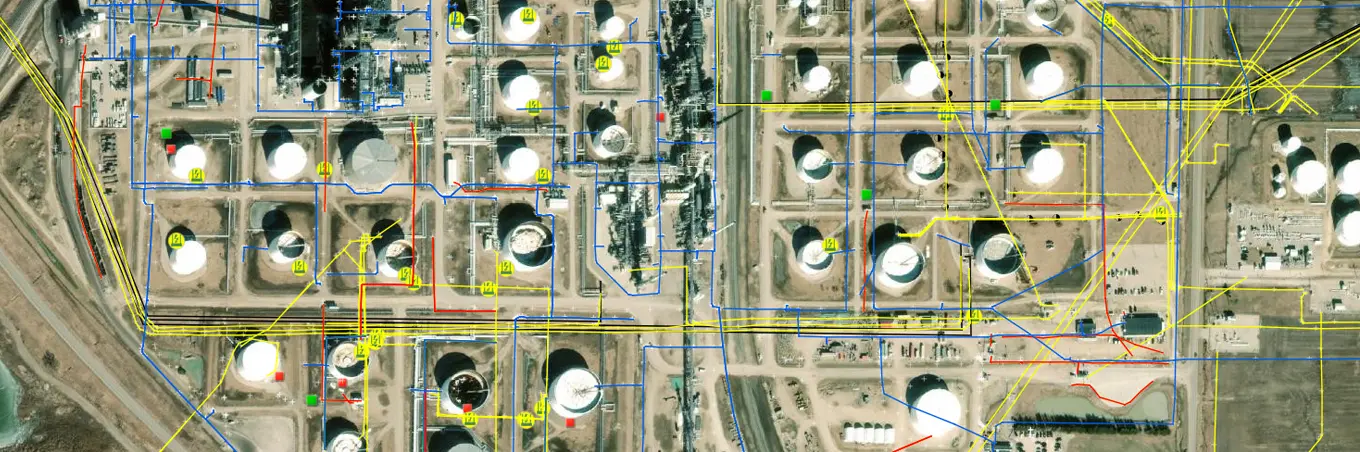

- Product storage

- Plant utilities and infrastructure

Scope of work

- Owner’s engineering

- Project management

- Engineering oversight

- Schedule coordination

- Cost control

- Contract negotiation

Project summary

Audubon provided the owner’s engineering for a ZeoGas methanol plant in East Texas. The 1.8-MTPA methanol production plant utilized licensed MegaMethanol technology from Air Liquide.

As the owner’s engineer, Audubon administered interface and integration guidance to ensure adherence to project specifications by the engineering-procurement-construction (EPC) providers, technology licensors, and equipment suppliers. Audubon also provided project management, lead engineering, documentation, and

technical review guidance of the facility design, including process- and engineering-related disciplines.

From planning and development through commercial operation, Audubon owner’s engineering and project management services enabled ZeoGas to begin processing clean methane sources in its efforts toward sustainability and reduced environmental impact.