Client

Location

Piping Upgrade for Water Cooling + Heavy Vacuum Gas Oil

Project overview

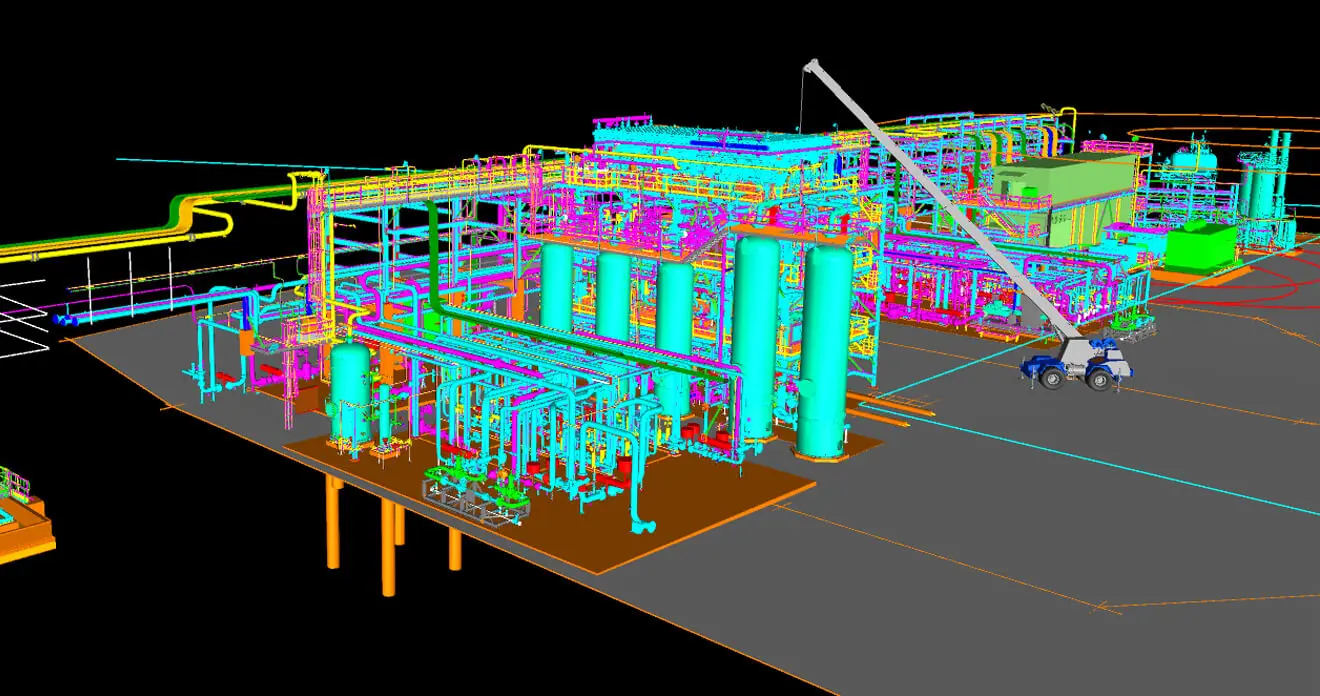

- Brownfield expansion

- Metallurgy upgrade to 317L

- Pipe rack upgrade

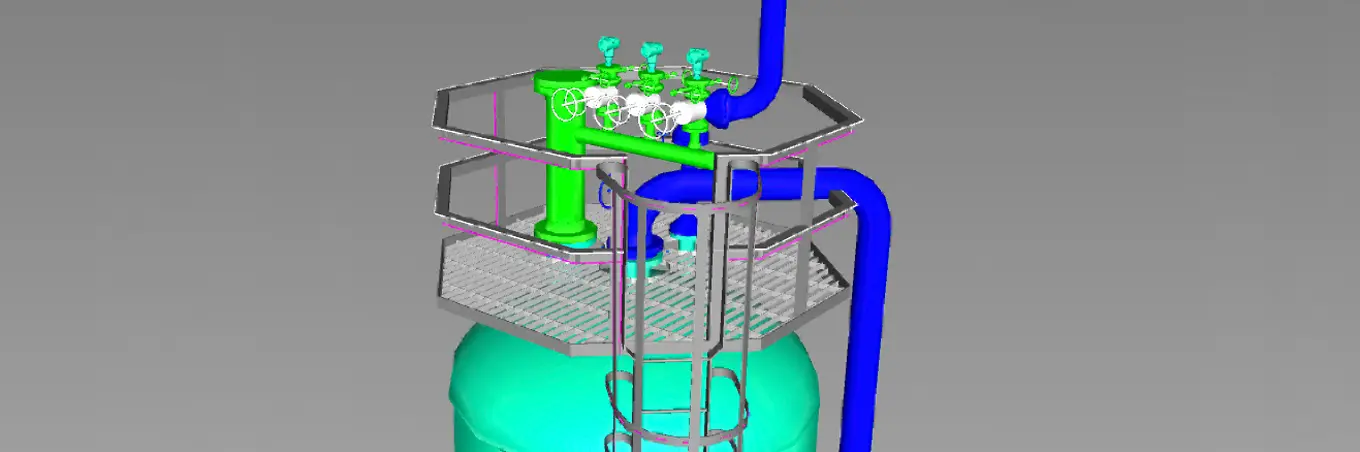

- Valve and instrumentation replacement

- Instrument specification update

Scope of work

- FEED

- Detailed engineering & design

- Project management & procurement

- Automation & control

- Construction & TAR management

- Stress, relief system, & process safety analyses

- Process hydraulics validation

- Inspection

Project summary

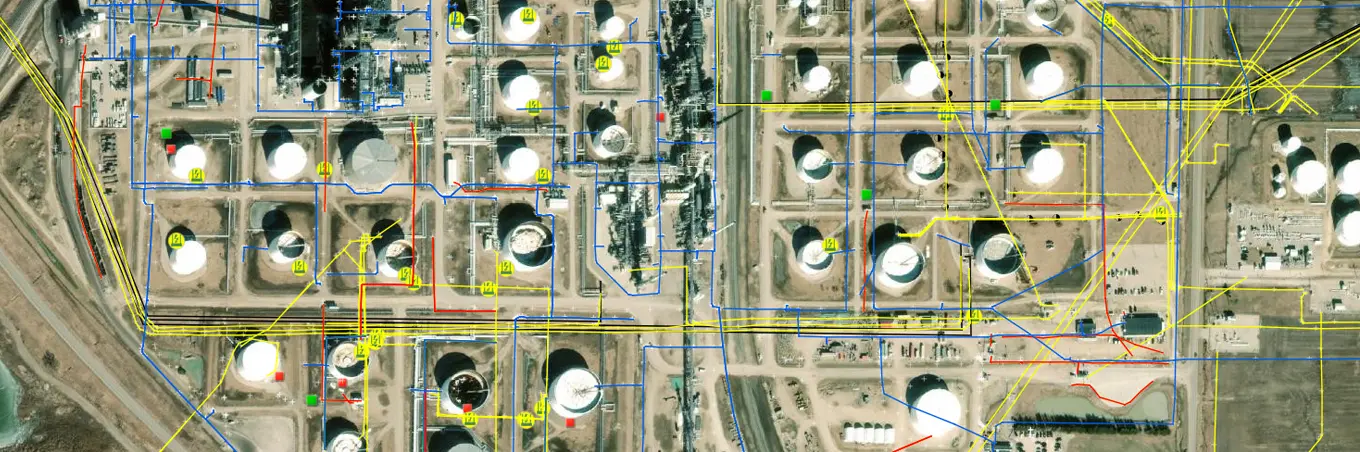

Audubon was contracted by Marathon Oil to provide front-end engineering and design (FEED), detailed engineering and design, procurement, and construction management (EPCM) for the replacement of defective water-cooling piping and valves (7,000 ft. of 30-in. pipe). The project also included in-line replacement of

2,600 ft. of heavy-vacuum-gas-oil (HVGO) piping with 317L stainless steel, as well as upgrades to all control valves and instrumentation.

The FEED, EPCM, and turnaround (TAR) management services supplied by Audubon expedited construction, prevented unnecessary disruptions, and enabled an efficient, effective return to water-cooling and HVGO operations for the E&P company.

Related Featured work