Fractionation Control System Upgrade

Project overview

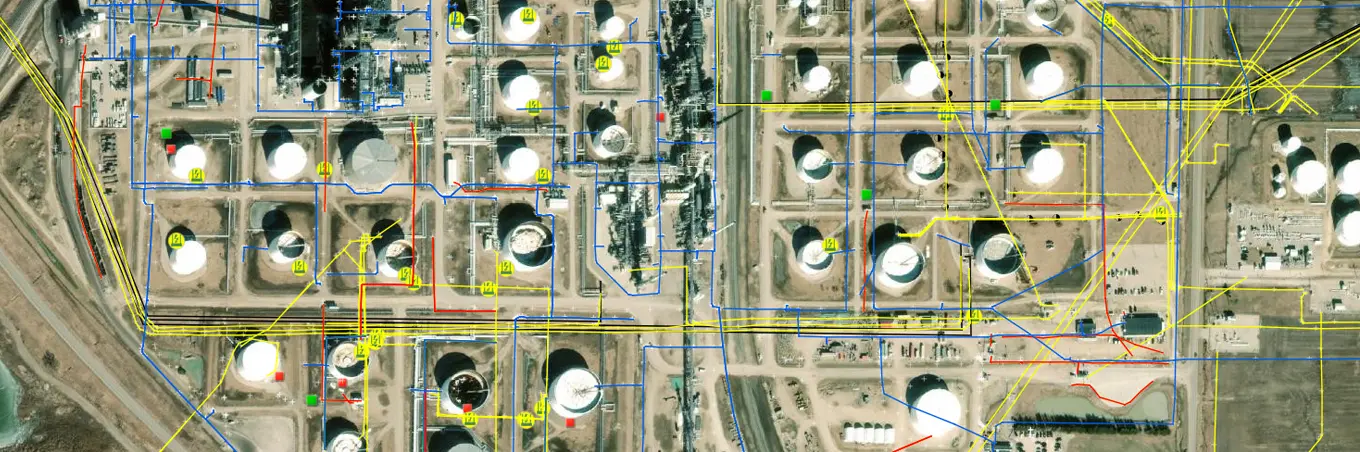

- Brownfield fractionation plant

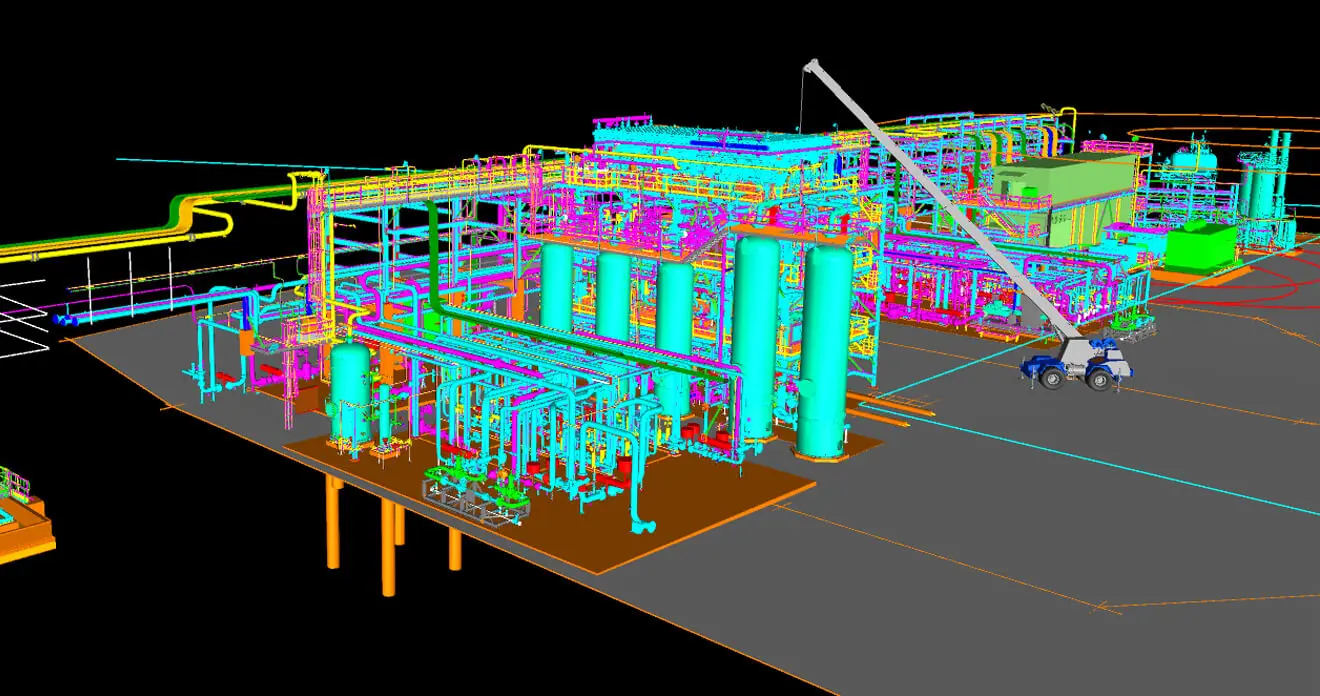

- ICS upgrade

- Yokogawa CENTUM VP DCS

- Allen-Bradley ControlLogix PLC

Scope of work

- Main automation contractor (MAC)

- Programming & communications

- Factory & site acceptance testing

- Commissioning & field startup support

- Schedule coordination

- Project controls

Project summary

Audubon was contracted by a large midstream oil and gas company to upgrade and segregate an existing industrial control system (ICS) for a fractionation plant in the Marcellus Shale. The upgraded ICS included a separate basic process control system (BPCS) using a Yokogawa CENTUM VP distributed control system (DCS) and a safety instrumented system (SIS) using an Allen-Bradley ControlLogix programmable logic controller (PLC) with SIL1 and SIL2 safety-instrumented functions.

Audubon’s scope of work included BPCS programming, SIS programming, communication between the BPCS and SIS systems, testing, and field startup.

After the fractionation control system upgrade by Audubon, the midstream operator was able to accurately and efficiently separate its natural gas liquids (NGLs) for application.