Want to share this article?

Are You Ready? PHMSA Issues New Rules to Overhaul Pipeline Safety – Part 1

In September 2019, the Pipeline and Hazardous Materials Safety Administration (PHMSA) published the “Mega Rule”.

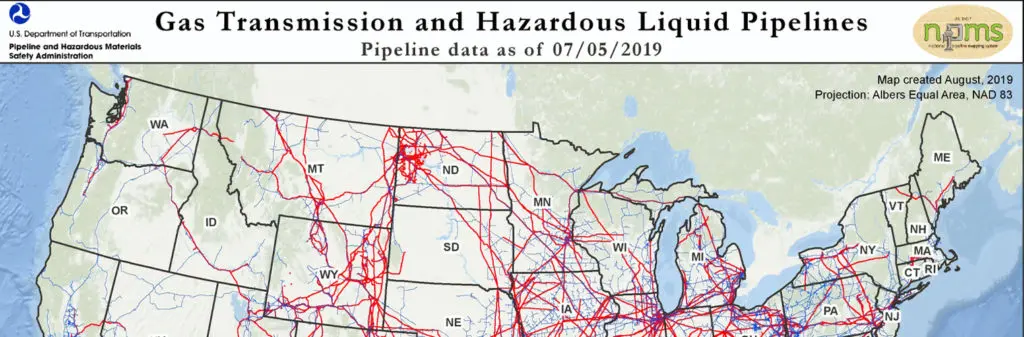

Part of these new regulations focus on the design, construction and operation of hazardous liquid transmission pipelines throughout the U.S.

Read further along to learn more about the PHMSA’s significant revisions to pipeline safety regulations and what the Mega Rule means for pipeline owners and operators.

Safety of Hazardous Liquid Pipelines

PHMSA sent to the Federal Register for publication a final rule in response to congressional mandates, National Transportation Safety Board (NTSB) and Government Accountability Office (GAO) recommendations, lessons learned and public input. It is amending the pipeline safety regulations to improve the safety of pipelines transporting hazardous liquids.

New Requirements:

- Annual, accident and safety-related condition (SRC) reporting requirements for certain hazardous liquid gravity and rural gathering lines.

- Post-weather related event (WRE) inspection of pipelines affected by extreme weather and natural disasters; tropical storms, hurricanes, floods, landslides, or earthquakes.

- Integrity assessment (hydrotest, ECDA or ILI) at least once every 10 years for onshore hazardous liquid pipeline segments located outside of high consequence areas.

- Extending the required use of leak detection systems beyond high consequence areas to all regulated, non-gathering hazardous liquid pipelines, e.g. transmission pipelines.

- All pipelines located in high consequence area (HCA) direct or could affect areas accommodate in-line inspection (ILI) tools within the next 20 years.

- Identify and verify all HCA direct or could affect line segments annually.

- Integration of integrity management program (IMP) data and consideration of spatial relationships among anomalous information.

The effective date of this final rule is July 1, 2020.

The hazardous liquid pipeline safety requirements highlighted here consist of Part 1 of what is anticipated to be a three-part rulemaking; commonly referred to as the “Mega-Rule”.

Current and future rulemakings will impact hazardous liquid and gas transmission as well as gathering and distribution pipelines. Since these rules are mandated safety requirements under 49 CFR Parts 192 and 195, Operators are required to implement procedures and practices that satisfy the regulatory requirements.

Audubon’s Advanced Pipeline Integrity Solutions for New Mega Rule Compliance

Through Audubon Companies’ integrated, data-driven and practical approach to pipeline regulatory compliance, asset integrity and corrosion protection, we can successfully help our clients comply with these new requirements.

Our Asset Integrity & Corrosion team consisting of pipeline designers, field technicians, operators and technical specialists, brings a depth of experience to address the challenges that accompany pipeline design, construction, operation and maintenance – safely and efficiently.

Specific to Mega-Rule Part 1, hazardous liquid pipeline requirements, Audubon Companies can help manage risk, assure compliance and optimize performance by the following:

- Review and modify written operations & maintenance, IMP and oil spill response programs to address new regulatory requirements.

- WRE segment identification and pre-emptive measure recommendations.

- Update and maintain geo-referenced asset maps and records for regulated and unregulated pipelines.

- Review and update pipeline design and construction standards to accommodate ILI tools.

- Provide pipeline make-piggable engineering, procurement and construction management (EPCM) services.

- Provide integrity management assessment services.

- Perform and update pipeline HCA, emergency flow restriction device (EFRD), risk and leak detection sensitivity analyses.

- Develop, update, and maintain pipeline asset geospatial data integration and storage platform (ESRI).

- Perform field data collection and testing.

Contact Audubon Companies today to discuss your pipeline assets and how we can help align your current structure and operations to meet the new pipeline safety rules issued by PHMSA.

For more information, please visit auduboncompanies.com.