Want to share this article?

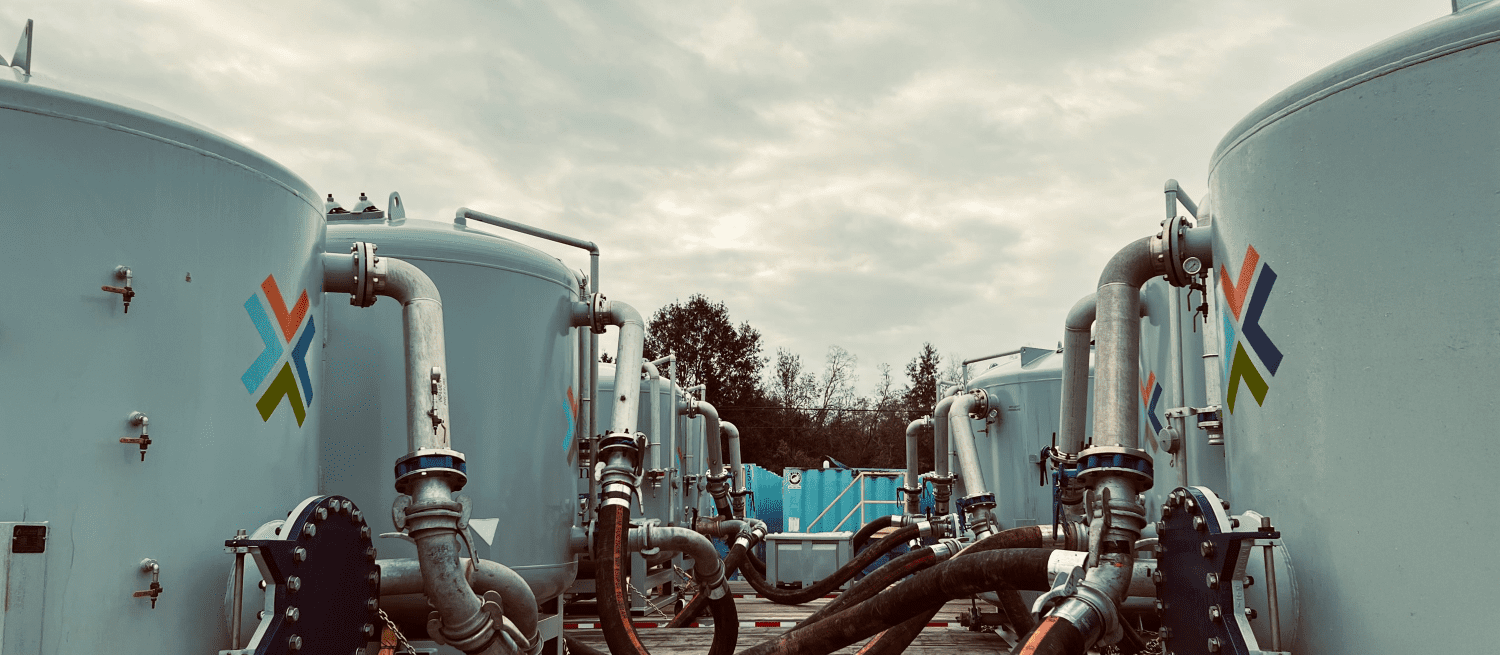

Operations and Maintenance Planning Keeps Oil and Gas Facilities Efficient

From auto manufacturers to oil and gas refiners, facility managers are always interested in increasing operational efficiency and improving the effectiveness of maintenance tasks.

As profit margins thin, competition increases, and safety planning becomes more important, the demands on operations and maintenance (O&M) personnel grow weightier. Operations must be made more efficient, systems must be optimized, and maintenance dollars must stretch further. Enter the O&M program.

The concept of O&M planning varies depending on who’s approaching the topic. The U.S. Department of Energy’s Federal Energy Management Program focuses heavily on energy and water efficiency (PDF), while the Environmental Protection Agency’s O&M programs may focus on minimizing exposure to a specific contaminate such as asbestos. However, a more general approach to O&M is more common, placing emphasis on the functionality and efficiency of a facility and its operations. The National Institute of Building Sciences takes this approach, describing O&M as “the day-to-day activities necessary for the building and its systems and equipment to perform their intended function.” Undoubtedly, applying careful planning and program management to infrastructure fits in well with the various onshore and offshore facilities run by the oil and gas industry today.

While many companies choose to create and manage their own programs and services, others turn to external O&M experts to provide staffing options and turnkey services. Upswings in monthly production quotas, for example, may necessitate the addition of staff knowledgeable in mechanical systems, electrical systems, and production management on short notice. Likewise, businesses requiring valuable insight into their existing O&M policies and how they can be improved can turn to a professional third-party examination of production schedules, preventive maintenance programs, and regulation and standard implementations. Of course, O&M consideration shouldn’t begin when the facility goes operational; mindful, well-considered facility design and construction can go a long way towards a more efficient O&M program later.