Want to share this article?

Avoiding Corrosion and Emissions Problems in Petrochemical Storage

In early 2015, one of the major stories in U.S. oil production was of shrinking storage space for petrochemicals.

“Storage is king,” proclaimed commodity finance expert Jean Francois Lambert, as market speculators took an already significant glut of domestic oil and leased much of the remaining storage space for holding it. Today, onshore storage has become so sparse that some businesses are beginning to turn to offshore floating storage vessels to hold their oil, while others like the Louisiana Offshore Oil Port look to the market as an opportunity to increase storage capacity at their facilities. As such, it seems reasonable to take a brief look at what important considerations go into maintaining an effective onshore petrochemical storage tank.

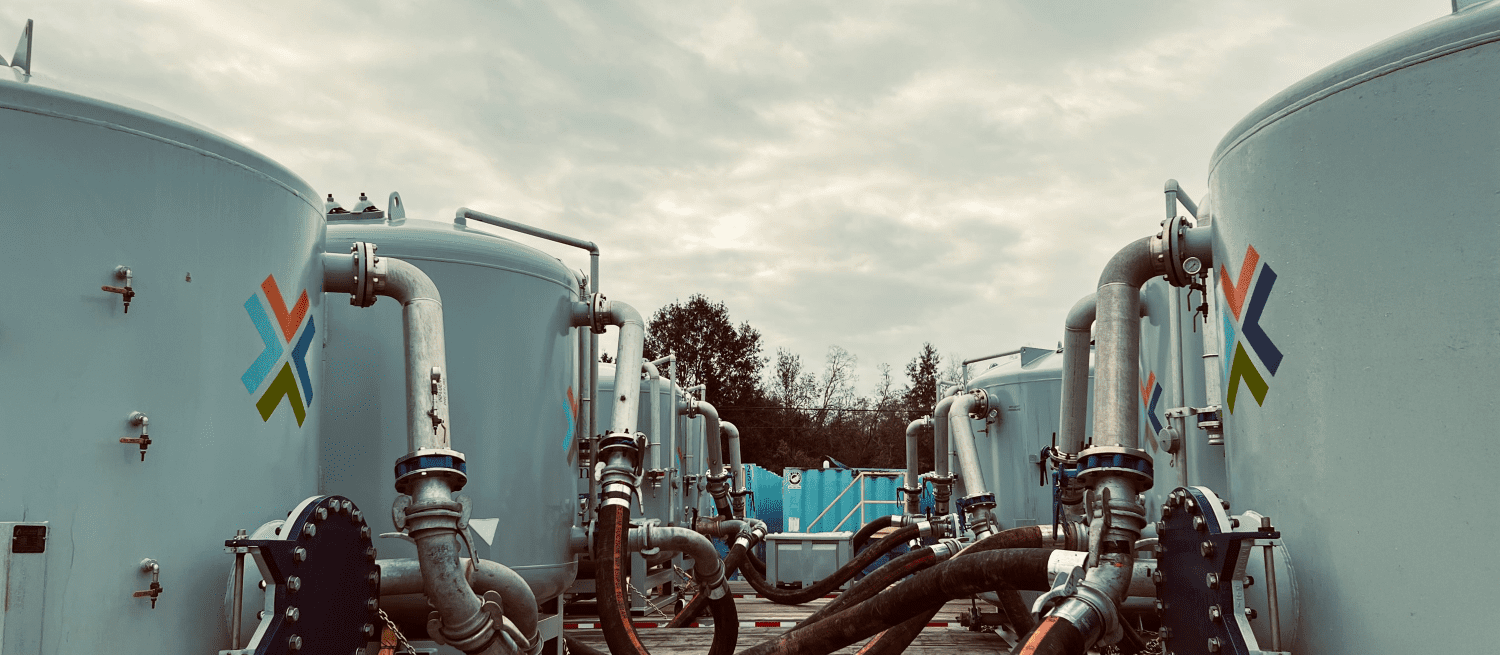

Limiting the effects of corrosion on storage tanks is vital to the longevity of an onshore storage system as well as the integrity of the fuels contained within. Inorganic chloride salts, sulphur-containing compounds, naphthenic acids, and water can all promote corrosion and must be dealt with in specific manners. Corrosion rates in aboveground storage tanks (ASTs) differ by location based upon the type of petrochemical stored within. Research presented by engineer Alec Groysman (PDF) at the NACE International Corrosion 2015 Conference and Expo found, for example, that shells and floating roofs of gasoline-containing ASTs were most likely to corrode, whereas crude-containing ASTs also tend to corrode at the bottom. Well-constructed ASTs minimize these effects by incorporating the right balance of material selection, fuel treatments, and protective coatings.

Another aspect of maintaining effective onshore petrochemical storage involves pollution control, including emissions. In a September 2015 compliance alert, the EPA identified the most common reasons storage vessels produce detectable emissions: inadequate design, sizing, operation, and maintenance of vapor control systems. As oil and natural gas is collected and moved to storage, pressure differences can cause hazardous air pollutants and greenhouse gases to flash off in vapor form. Additionally, changes in storage tank temperature and fill levels can also cause emissions problems. Vapor control systems must be integrated, operated, and maintained effectively to reduce the impact of those emissions on the environment. This requires knowledge of and experience with pressure management, flow rates, valve and separator designs, and combustion and recovery technologies to effectively reduce the environmental impact of emissions in storage infrastructure.

Of course, other considerations collectively go into the design of a storage facility and its long-term usefulness. Geological foundation, railroad access, ship and barge access, pipeline design, and manifold design all work into the equation and require cost-effective yet productive approaches. In the end, however, with a bit of careful design consideration, quality engineering, and a flexible maintenance plan, a new onshore petrochemical storage facility can yield decades of effective use and stable fuels for the market.