Want to share this article?

Proactive Approach to Asset Integrity Management

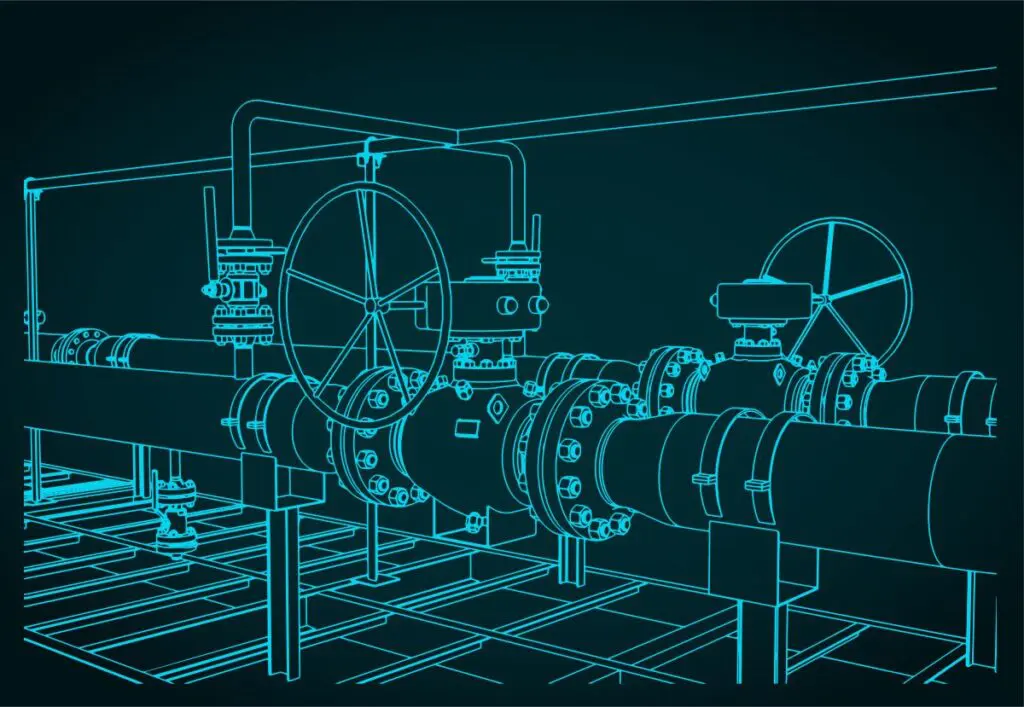

Asset integrity management has become increasingly important with many companies today electing to upgrade brownfield facilities in order to improve efficiency and extend operational life.

Oil and gas infrastructure across the globe is aging, and as it does, the task of managing the risks associated with its operation becomes more difficult. This is particularly the case in the offshore industry, where it’s estimated that more than 50% of all platforms built in the late 1970s and early 1980s have eclipsed their operational life by as much as 15 years (source: Oil and Gas IQ). Midstream infrastructure in North America is in a similar state – with almost half of U.S. crude oil pipelines having been built before 1960 (source: PHMSA).

The International Association of Oil and Gas Producers (OGP) defines asset integrity as follows

“asset integrity is related to the prevention of major incidents. It is an outcome of good design, construction, and operating practices. It is achieved when facilities are structurally and mechanically sound and perform the processes and produce the products for which they were designed.”

Asset Integrity Management and Operators

Many operators continue to approach asset integrity management on a reactive basis, in which issues with equipment and systems are addressed only after they’ve started to negatively impact the operation. In addition to higher maintenance costs, this often results in more unplanned downtime, increased risk, and an inability to meet strategic production goals.

Taking a proactive approach and identifying potential risk threats during the conceptual phase of a brownfield (or greenfield) project can help to avoid these problems. Equipment selection is a critical part of this process and it often has a large impact on how much time and resources will be spent on asset integrity management throughout the life of a facility.

Although selecting the most advanced solution is a route taken by many pipeline operators, it may not always be the most beneficial. This is largely due to the fact that more advanced systems typically have higher acquisition costs and highly specific manpower requirements. In some cases, the more advanced choice may also be “overkill” – resulting in unnecessary complexity and a significantly lower return on investment (ROI).

Engaging early with contractors and vendors to ensure that a system, technology, or piece of equipment is optimal given the specific requirements of a project is key to prevent and minimize unnecessary integrity management costs of oil and gas facilities.