Want to share this article?

5 Ways 3D Laser Scanners Can Improve Facility Safety

3D laser scanners have become commonplace throughout the oil and gas industry for many reasons, not least of which is the speed and accuracy they offer over traditional surveying techniques.

However, many operators have also started to take advantage of the benefits they provide when it comes to jobsite safety and incident prevention.

Listed below are five examples of how 3D laser scanners can improve safety at a jobsite and/or facility.

1. PROACTIVE MAINTENANCE

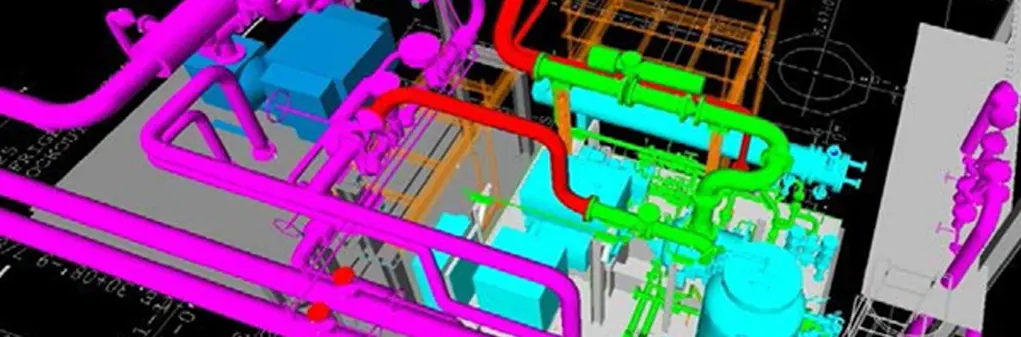

3D laser scanners can generate a highly detailed geometric representation of an object, surface or environment – allowing engineers and facility managers to locate hazards that they would not have been able to detect using conventional survey equipment. 3D scans can be especially valuable when it comes to proactive maintenance, as they help to identify potential issues before they become problematic.

2. IDENTIFYING HAZARDS

3D laser scans can gain access to areas that traditional survey equipment (and their crew) cannot. An example would be identifying a crack in a pipeline or a dangerous condition in a confined space. Representations are also generated in remarkable detail, which minimizes the likelihood of inaccuracy due to human error.

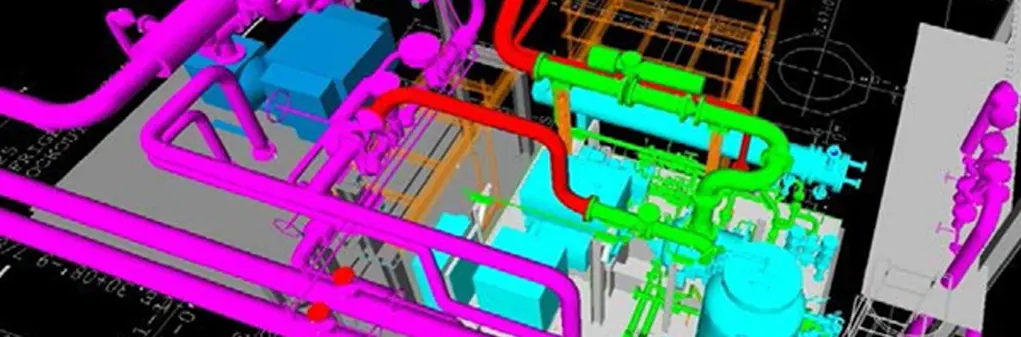

3. ACCURATE AS-BUILT OR AS-IS DOCUMENTATION

As any engineer knows, as-built drawings are notoriously incomplete (and sometimes inaccurate). A 3D laser scan can provide fast, accurate as-is documentation, which allows operators to identify conditions that can create hazardous conditions and make more informed decisions about their facility.

4. MONITORING CHANGE

A 3D scan performed in the preliminary phases of a project can act as a baseline in instances when shifts and/or changes caused by environmental conditions are a concern. By scheduling regular scans, operators can monitor these changes to determine if they are creating an unsafe environment. An example of this is would be monitoring a dynamic environment/process with a high number of moving parts.

5. REDUCING WORKER EXPOSURE

3D scans can be done from a distance, eliminating the need for a survey crew to enter a dangerous environment. The distant scan is also an advantage if an event has caused uncertain conditions in a space. Scanning from afar allows crews to assess the structural and mechanical integrity of a facility before sending personnel in to perform work on it.