Want to share this article?

Using Cryogenic Separation for NGL Extraction 101

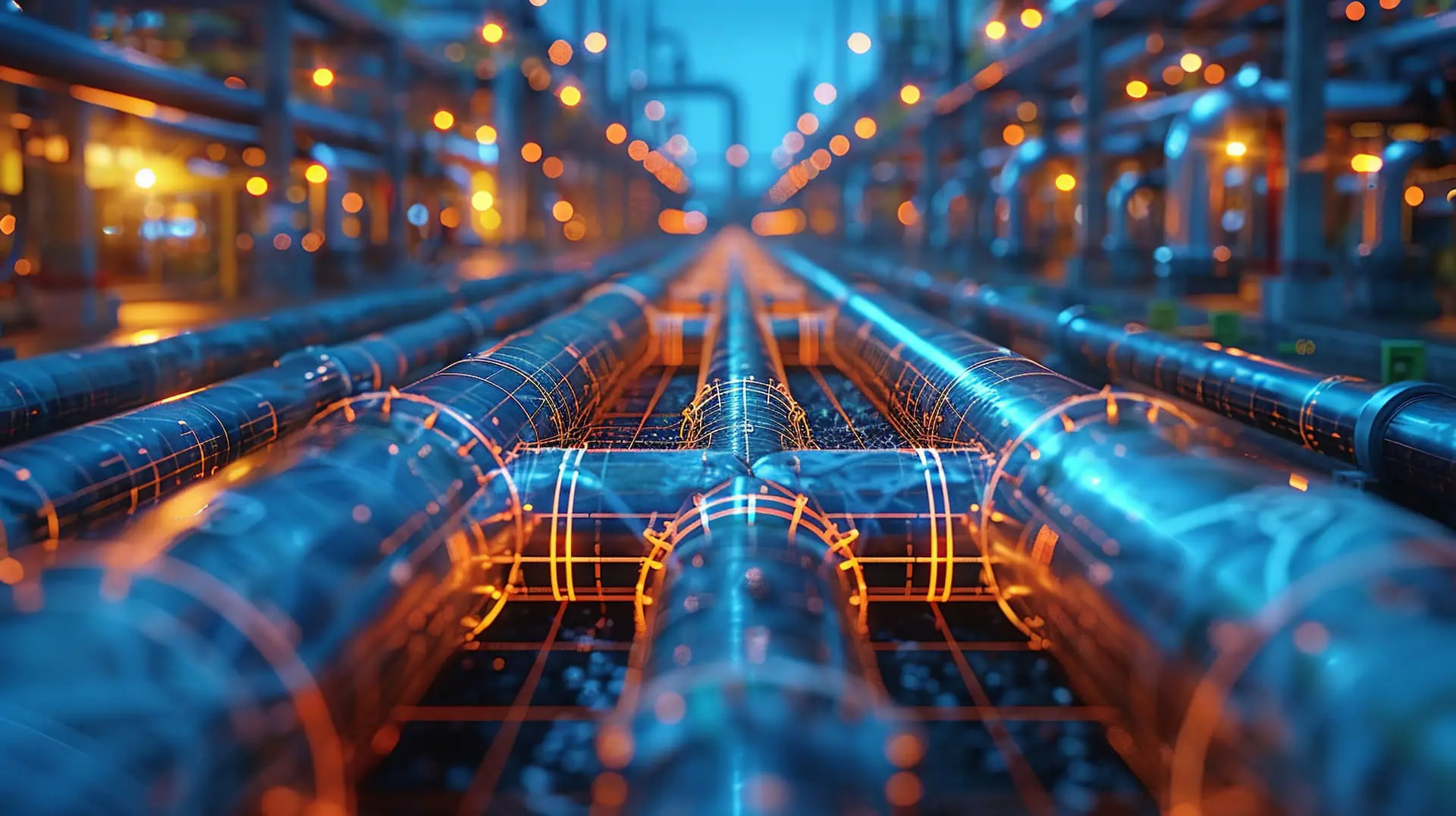

Cryogenic separation is a processing operation that is commonly used to extract natural gas liquids (NGLs) from raw natural gas.

Unlike absorption methods, which are used primarily for extracting heavier NGLs, cryogenic processes are used to separate out lighter hydrocarbons such as ethane, propane, and butane from an incoming stream.

During the process, refrigerants are used to cool the gas stream to very low temperatures. Expansion turbines then push the gas through a narrow pipe into an expansion chamber. When the gas enters the chamber, its vapor pressure drops, causing it to cool even further (typically to around -120 degrees Fahrenheit). At this temperature, methane (an extremely light hydrocarbon) stays in the stream, while the other heavier hydrocarbons condense into liquid form and flow out.

To separate these NGLs from one another, the liquid mixture is then passed through additional chambers where it is progressively warmed. Each NGL has its own unique boiling point and by controlling the temperatures within the different chambers, each specific hydrocarbon can be systematically removed and collected.

With ethane recovery rates from the gas stream ranging from 90 – 95%, cryogenic separation is typically one of the most efficient methods of NGL extraction. The expansion turbine used in the process can also be configured to harness some of the energy released during the expansion process to recompress the gaseous methane effluent, which ultimately results in lower energy costs.

Aside from propane, which is a very important standalone fuel, NGLs are most commonly used as petrochemical feedstock and as blending and processing components in a wide range of refining processes.