Want to share this article?

Using Technology to Overcome the Challenges of Pipeline Routing

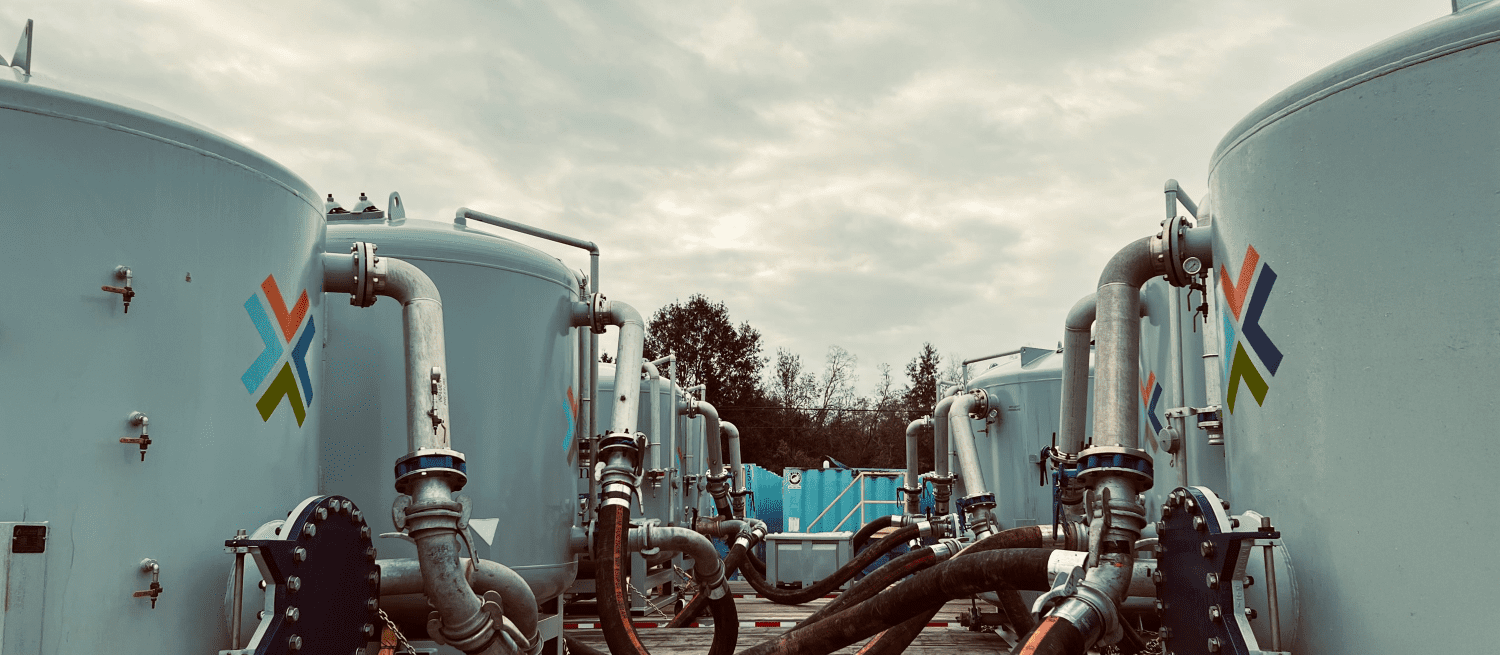

In today’s digitally driven environment, getting oil and gas from the wellhead to the consumer as a refined product requires extensive knowledge and practical application of advanced technologies by professionals from a variety of fields.

The early stages of pipeline placement are no exception, requiring careful insight, planning, and due diligence to ensure that newly built routes are safe, effective, and profitable.

Keeping this in mind, owners and operators must be cognizant of the trade-off between “accuracy vs. cost” (or “time vs. money”) when planning a pipeline. Striking a balance between the two is critical not only to the long-term success of the pipeline itself, but also to the safety and well being of the environment and the people who will inhabit the area for many years to come.

WEIGHING THE OPTIONS

Routing a pipeline requires consideration of many factors, including topography, soil characteristics, ecosystems, and safety, as well as local, state, and federal regulations. While finding the shortest route is often a worthy endeavor, it usually is not optimal due to such constraints.

For instance, maybe the soil is not resistive enough, or the population is set to increase significantly along a proposed route; or maybe additional permits will be required to build a route over an environmentally sensitive area. All of these have the potential to derail a plan, ultimately resulting in higher costs, schedule delays, and decreased ROI.

GIS and GPS technologies are helping owners and operators avoid these shortcomings, and they’re simplifying pipeline planning operations in the process.

ACCURACY VS. COST

Current GPS technology can produce impressive levels of accuracy. However, developing maps and numerical data for planning a pipeline route that is accurate down to the inch is usually unnecessary, in part because backhoes and other equipment will disturb the survey stakes regardless. In other words, spending the extra resources to achieve a higher level of precision can be detrimental to the profitability of a pipeline project, and with no added benefits to show for it in terms of safety or environmental friendliness, the pay off simply is not there.

In some cases, companies may need to budget for higher accuracy, especially when working in inhabited areas and heavily developed parts of major cities. A higher level of accuracy is also necessary in developing as-built drawings of the completed pipeline. Companies typically focus on ensuring that the final drawings accurately indicate what’s in the ground.

Accuracy of GIS and GPS models can also be beneficial when it comes to examining the potential environmental effects of pipeline placement due to the fact that simulation tools and algorithms use field data to identify the best possible option. GIS and GPS technologies are helping owners and operators avoid these shortcomings, and they’re simplifying pipeline planning operations in the process.

AN INTERATIVE PROCESS

The International Pipe Line & Offshore Contractors Association (IPLOCA) defines pipeline routing as “an iterative process, which starts with a wide ‘corridor of interest’ and then narrows down to a more defined route at each design stage as more data is acquired, to a final ‘right of way’ (ROW).” This iterative appraisal process requires a phased approach, one that first involves desktop studies and the development of models that take advantage of geological, satellite, population, and engineering data.

Once a rough corridor is planned, additional data can then be collected using GIS, laser imaging, and other mapping technologies. A legal team must investigate the varying regulatory environments and laws that affect the route as well as what efforts will be required for approval from both stakeholders and governments. Environmental impact is factored into this research, including potential disruption of ecosystems and the likelihood of population increase along the route. Through all of this, alternate routes should be planned in the unlikely event that other factors render the primary route unusable. Companies now have to be more prudent when it comes to route selection, making land acquisition and right-of-way management more important than they have ever been.

THE BOTTOM LINE

In recent years, the pipeline planning process has grown increasingly difficult as areas have become more and more congested. Companies now have to be more prudent when it comes to route selection, making land acquisition and right-of-way management more important than they have ever been.

With over 3,000 companies operating oil and gas pipelines in the U.S., newly built lines often have to run above, below, or across existing rights of way. Power lines can also complicate matters due to the fact that when built in close proximity with steel pipelines, stray current (induced alternating current) can cause corrosion.

The key to completing a successful pipeline project is to identify any and all potential sources of trouble before construction even begins. Capital expenses typically account for the large majority of pipeline costs, and as a result, being able to use advanced GIS and GPS technologies to identify these trouble spots can have a significant impact on project success.

To learn more about pipeline planning, read our article in the July issue of “Pipeline and Gas Journal” here.

ED NORTHROP

Director of Oil & Gas – Utica & Marcellus Region

Ed Northrop is the Director of Oil & Gas for the Marcellus, Utica, and Northeast U.S. Region at Audubon Field Solutions. He has over 30 years of experience in oil and gas operations, pipelines, and facilities projects. Ed was with National Fuel Gas for 25 years. In his current role, Ed manages client relations, develops new business opportunities, and provides insight on the market particular to the Marcellus, Utica, and Northeast U.S. region. He earned a degree in Petroleum Technology from University of Pittsburgh and a degree in Engineering Technology from Pennsylvania State University.