Want to share this article?

Applications of Automation in the Onshore Environment

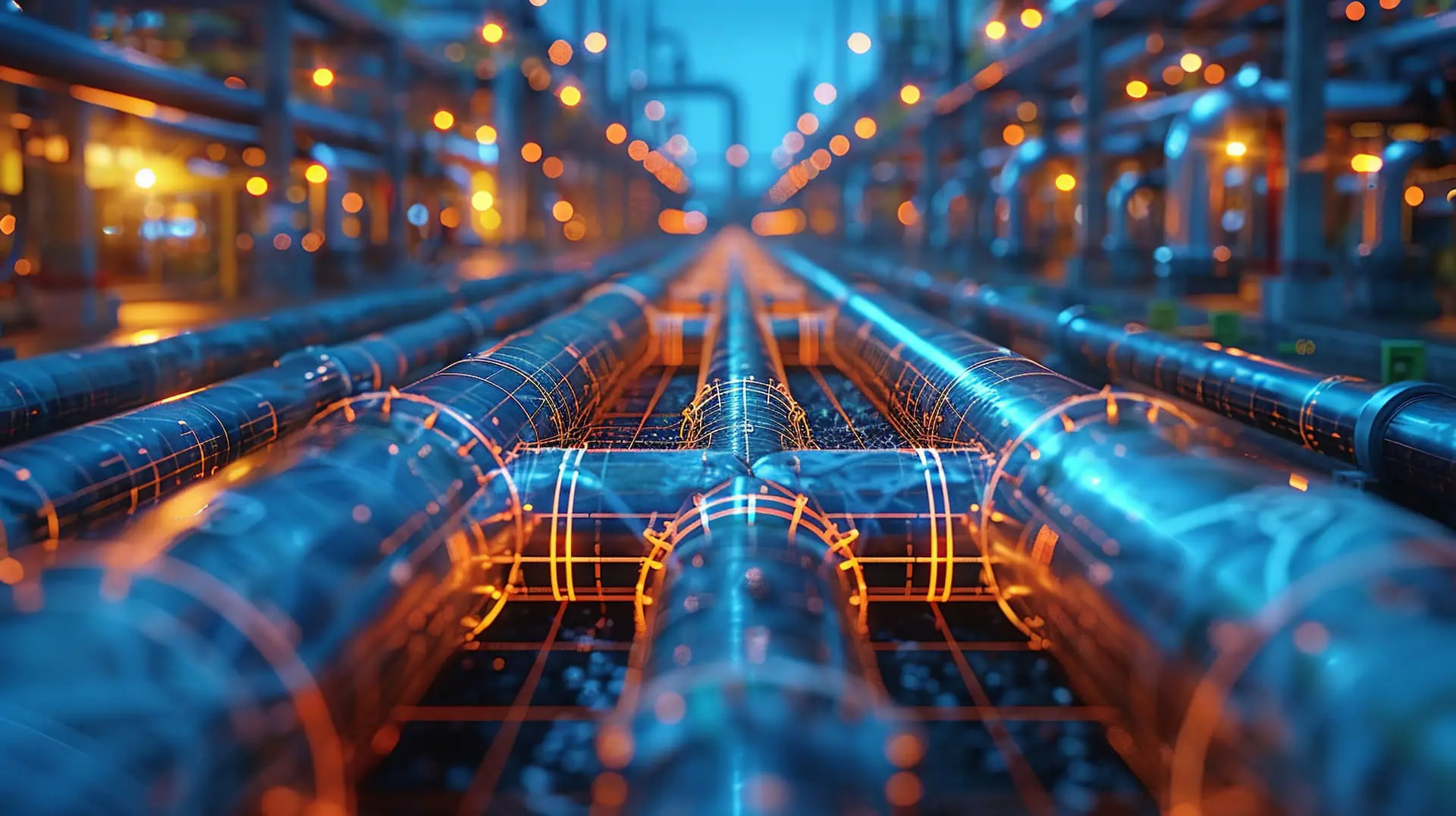

From oil wells to pipelines, onshore upstream and downstream vendors are seeking to improve their infrastructure to be more efficient.

Removing the human element from dangerous tasks and improving existing mechanical systems drives many companies to turn to automation. However, integration of automated systems requires careful consideration of business processes. Onshore automation systems must not only address control and report requirements but also mitigate risks and assist producers with process challenges.

SCADA (supervisory control and data acquisition) systems are at the heart of most automation efforts both onshore and off. Various hardware and software components work together to collect information from sensors attached to various infrastructure components and then analyze and display the information in a meaningful way. For example, pressure, temperature, and flow sensors as well as field controllers can be applied to drills, valves, pipelines, and storage tanks. The associated data from those sensors can be used to improve well efficiency, monitor custody transfers, trigger alerts, engage emergency shut-down systems, or even guide future brownfield developments.

Artificial lift automation is also common onshore. When integrated into one or a series of wells, artificial lift pumping systems can reduce energy consumption, decrease rates of mechanical failure, and improve well production. A control unit interfaces with a motor-mounted control mechanism on the pumping system directly or wirelessly. Fine manual or automatic adjustments can be made to the pumping mechanism to both maximize production and identify component wear. In many cases adjustments and shutdowns can be made based on variables such as fluid volume across multiple wells.

Robotics represents another automation element employed in the onshore environment. During 2013’s IEEE International Conference on Mechatronics and Automation, representatives of The Petroleum Institute outlined the major applications of robotics in the onshore oil and gas industry’s “upstream and downstream process[es] such as pipe handling in drilling operations, pipe inspection, tank inspection, and remote controlled underwater vehicles (ROVs).” Multinational oil and gas company Ensco, for example, has managed to integrate pipe handling robotics into both onshore and offshore applications to greatly improve pipe and casing installation. And services company KTV Group touts its robotic tank cleaning and inspection tools as saving water, reducing implementation time, and minimizing the need for human interaction.