Packaging Line Engineering + Migration

Project overview

- 400+-mile migration of stainless steel slitting & packaging lines

- Control-system reprogramming

- Allen-Bradley control equipment

Scope of work

- E&I field analysis

- Installation engineering

- Automation engineering

- Optimization of fit & controls for new location

- Deployment, commissioning, & startup

Project summary

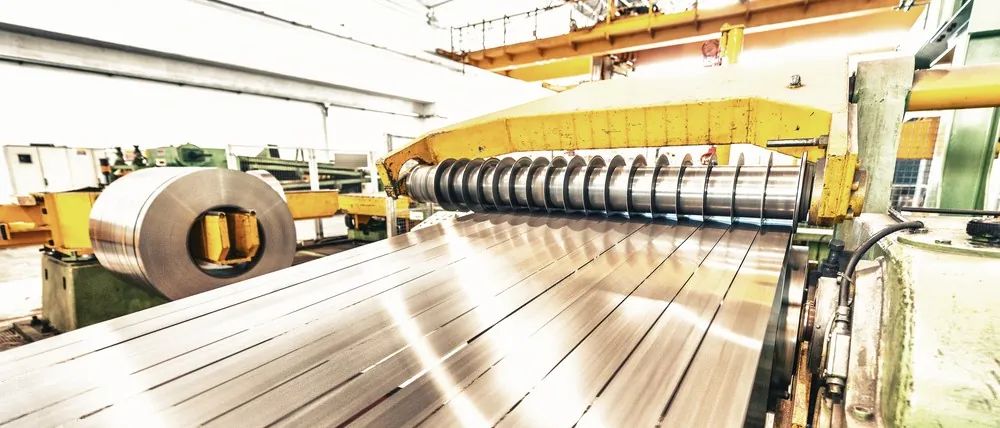

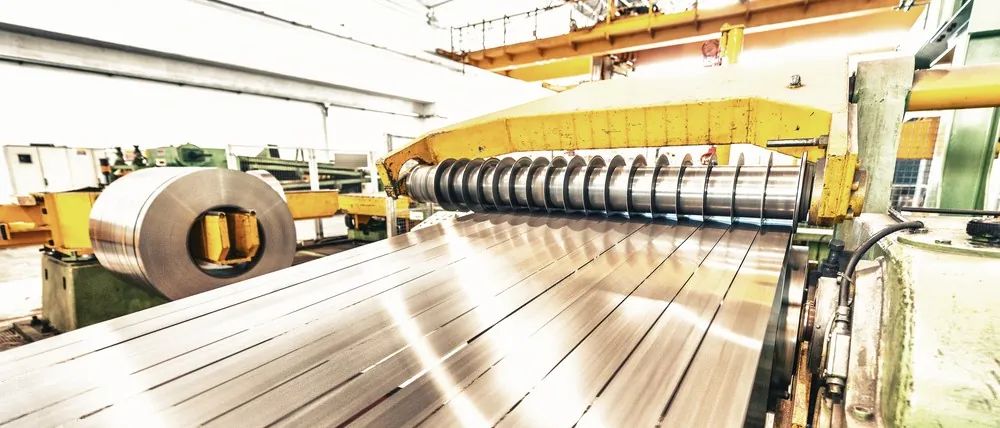

Audubon was contracted for slitting and packaging line engineering and migration services at a specialty steel-finishing facility in Pennsylvania. The slitting and packaging lines were moved more than 400 miles from the midwestern United States.

For the slitting line, Audubon engineered the migration of the line and all components, including the decoilers and feeders, press cutter, coiler, transfer cars, and downender. An electrical and instrumentation (E&I) field analysis was performed of the original installation, with deliverables including embedded conduit plans, conduit cable schedule, and interconnect drawings. Advanced civil and structural engineering practices were applied for the foundation and placement to optimize the fit and function of the slitting line in its new location.

For the packaging line, Audubon automation experts made mechanical, electrical, and programming modifications to the bander, stacker, turntable, and stretch wrapper. The line was reoriented from 180° to 90° operation and was engineered to process in the reverse direction from the original design. Working with multiple Allen-Bradley SLC platforms and PanelView human-machine interfaces (HMIs), the team integrated the various equipment into a highly complex and cohesive process to ensure tension, speed, knife rotation, feeding, conveyance, and safety. Finally, Audubon deployed, commissioned, and started up the packaging line for efficient, reliable operations.