Client

Location

Steam Controls System Upgrade

Project overview

- Replaced existing programmable logic controllers (PLC)

- Replaced PLC hardware

- Updated PLC panels and controls

- Replaced existing VFDs

- Developed human-machine interface screens

- Updated network and data communications

- Worked seamlessly with the supply chain

- Supported contractor demolishing and installation

Scope of work

- Project management

- Detailed design review

- Demolition design package for contractors

- Control design and upgrade services

- Submittals documents and schematics

- Startup & commissioning services

- PLC programming

Project summary

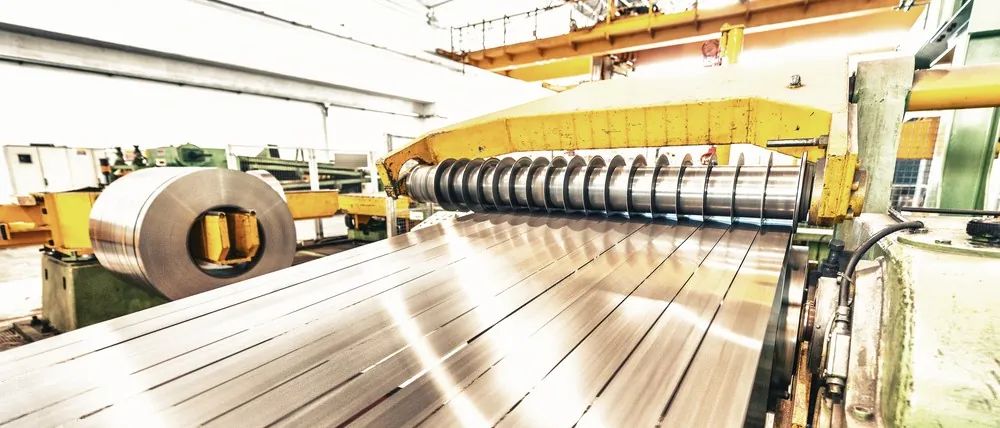

The world’s leading producer of Concord and Niagara-based grape products contracted Audubon to upgrade a major steamer control system of two legacy boilers. The control system provides critical temperature control for the juice and jelly production facility.

The project included design services and full demolition of existing control panels, variable frequency drives (VFD), and local control stations. The automation team upgraded the dated hardware with new Allen-Bradley ControlLogix and Yaskawa VFDs, which improved operational efficiency and system performance at the manufacturing facility.

Related Featured work

audubon

Discover how we deliver project excellence to our clients

With our multidisciplinary approach, we generate custom solutions in every phase of the project lifecycle.